Reclaiming Alcohol from Expired Products: A Smarter Way to Reduce Waste

Reclaiming Alcohol from Expired Products: A Smarter Way to Reduce Waste

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

Have you ever wondered what happens to expired bottles of wine, old hand sanitizers, or unsold perfumes? While they may no longer be good for their original use, the alcohol inside them often remains perfectly usable. Instead of throwing them away, that alcohol can be reclaimed, purified, and reused.

This process—called alcohol recovery—is a growing trend in sustainable industries. It helps companies reduce waste, cut costs, and protect the environment, all by giving expired products a second life.

Why Reclaim Alcohol?

Alcohol, especially ethanol, is a stable compound. It doesn’t “go bad” the way food or medicine does. Even if the smell, color, or taste of a product changes over time, the alcohol inside it stays chemically strong and usable.

So why waste it? With the right technology, expired alcohol-containing products can be turned into:

- Disinfectants and hand sanitizers

- Industrial cleaning fluids

- Biofuel and energy products

- Even new alcoholic beverages (in licensed facilities)

What Kind of Products Can Be Recycled?

Many types of expired goods contain recoverable alcohol:

- Beer, wine, and spirits

- Perfumes and body sprays

- Mouthwash and cosmetic toners

- Hand sanitizers and rubbing alcohol

- Pharmaceutical syrups and herbal extracts

Rather than sending them to landfills, companies can send them to special facilities that extract the alcohol safely and cleanly.

How Does It Work?

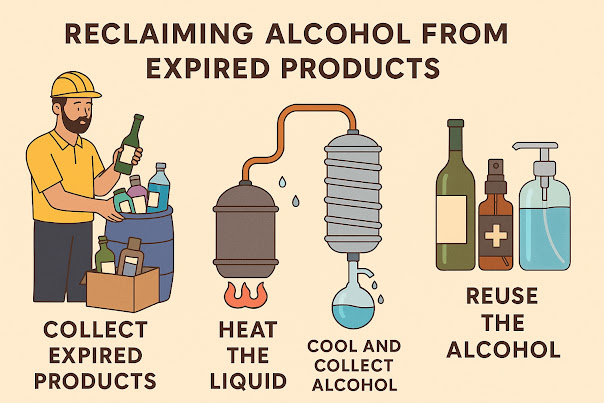

The process is based on distillation, which simply means separating alcohol from other ingredients by heating the liquid.

- Collect expired products

- Filter and separate the liquids from packaging

- Heat the liquid so the alcohol turns into vapor

- Cool the vapor into clean, usable alcohol

- Store and repurpose the alcohol for new uses

It’s similar to how alcoholic drinks are made, but this process focuses on recycling.

Benefits of Alcohol Recovery

Legal and Safety Matters

Because alcohol is a controlled substance in many countries, this process must be done by licensed companies with proper equipment and safety rules. These companies follow laws about fire prevention, pollution, and taxes.

Home distillation is usually not allowed and can be dangerous. That’s why alcohol recovery is handled by trained professionals in industrial environments.

Real-Life Examples

- In the U.S., during the COVID-19 pandemic, expired beer and wine were turned into hand sanitizers by distilleries.

- Some recycling companies now work full-time collecting expired products from stores and turning them into industrial-use alcohol.

- Countries like Germany, the UK, and Israel have guidelines for safe recovery of ethanol from unsellable stock.

Conclusion

Reclaiming alcohol from expired products is more than just a clever trick—it’s a responsible way to reduce waste and make the most of what we already have. Whether it’s an old bottle of wine or an outdated perfume, that alcohol still has value.

By recovering it, we help the planet, reduce business losses, and move toward a more circular, sustainable future.

Would you like a version of this article in Hebrew or an illustrated infographic to go with it?

Reclaiming Alcohol from Expired Products Including Alcohol: A Sustainable Recycling Method

By Ronen Kolton Yehuda (Messiah King RKY)

Abstract

This article presents a technical overview of alcohol recovery from expired products—including alcoholic beverages, hygiene products, pharmaceuticals, and extracts—through industrial distillation and reclamation processes. As global emphasis increases on waste reduction and resource circularity, ethanol recovery stands as a viable strategy for transforming waste into economic and environmental value. The paper details process engineering, feedstock types, legal standards, and end-product applications.

1. Introduction

Millions of liters of alcohol-containing products are discarded annually due to expiration, packaging failure, or market rejection. Despite product expiration, the ethanol component—being chemically stable and non-degradable—remains intact. Industrial facilities now implement controlled distillation systems to reclaim this ethanol, recycle it, and reintroduce it into the production loop.

2. Eligible Product Categories for Alcohol Recovery

| Product Type | Typical Ethanol Content | Notes |

|---|---|---|

| Alcoholic beverages | 4–50% | Beer, wine, spirits – commonly recycled |

| Perfumes and colognes | 70–90% | Ethanol with aromatic additives |

| Medical alcohol/disinfectants | 60–90% | Isopropanol or ethanol |

| Herbal tinctures/extracts | 30–80% | Contain ethanol as solvent |

| Mouthwash and cosmetic toners | 10–40% | Ethanol often mixed with glycerin or menthol |

| Pharmaceuticals (syrups, etc.) | 5–30% | Controlled substances require special handling |

All products must undergo screening and sorting to determine recovery potential and safety.

3. Alcohol Recovery Process Engineering

3.1 Pre-Processing

- Removal of packaging, labels, and caps

- Liquid collection through crushing or draining

- Filtration to eliminate particulates or gels

- Chemical analysis to determine alcohol purity and additional components

3.2 Distillation

Equipment:

- Stainless steel fractional distillation columns

- Heat exchangers for vapor condensation

- Reflux control systems to enhance separation accuracy

Process Overview:

- Heating range: 70–100°C, depending on the mixture

- Separation of ethanol (bp 78.3°C) from water and non-volatiles

- Vacuum distillation for heat-sensitive or complex formulations

- Optional molecular sieve drying for anhydrous ethanol (99.9%)

3.3 Post-Processing

- Denaturing (if non-consumable use):Methanol, methyl ethyl ketone, or bitrex may be added

- Purity testing:GC–MS or HPLC to confirm ethanol grade

- Storage and packaging:In corrosion-resistant tanks, drums, or IBC containers

4. Output Applications and Product Grades

| Output Grade | Alcohol Purity | Applications |

|---|---|---|

| Fuel-grade ethanol | 95–99% | Biofuel, additive to gasoline |

| Industrial-grade ethanol | 90–96% | Solvents, detergents, chemical intermediates |

| Sanitizer-grade ethanol | 70–95% | Hand rubs, surface disinfectants |

| Pharmaceutical-grade | 96%+ | Drug manufacturing, extraction solvents (USP standards) |

| Cosmetic-grade ethanol | 95%+ | Perfumes, aftershave, and skin care bases |

5. Environmental and Regulatory Aspects

5.1 Environmental Impact

- Reduces landfill and water pollution from expired alcohol disposal

- Supports circular economy in cosmetics, pharma, beverage, and fuel sectors

- Enables ethanol reuse without fossil-fuel fermentation processes

5.2 Regulatory Frameworks

| Jurisdiction | Key Regulation |

|---|---|

| USA | TTB and EPA licensing for industrial alcohol recovery |

| EU | Excise rules under Directive 2008/118/EC + REACH |

| Israel | Ministry of Health + Tax Authority permits required |

| Canada | Federal Excise Act and Environmental Protection laws |

Note: Special handling required for controlled drugs, denatured alcohol, or contaminated materials.

6. Industrial Implementation: Case Study Framework

Example Process Flow for Expired Product Recovery:

- Receive and log expired inventory (e.g., expired hand sanitizer)

- Mechanically uncap and crush packaging

- Filter and homogenize liquids

- Heat and distill in multi-stage system

- Separate ethanol fraction

- Repackage and/or denature for resale

Facilities:

- Equipped with automated material sorting

- Hazardous waste handling and fire safety compliance

- VOC capture and emission controls installed

7. Economic Value Chain

- Input: Expired goods from manufacturers, retailers, warehouses

- Processing: Centralized ethanol reclamation plants

- Output: Resalable ethanol (up to $800/ton depending on grade)

- Savings: Tax recovery, avoided disposal fees, and material reuse

8. Challenges and Limitations

- Variable compositions require custom distillation parameters

- Complex mixtures may produce low recovery yields

- Not all alcohol sources are economically viable (e.g., diluted cosmetics)

- Legal limitations on food- or pharma-grade reuse

9. Conclusion

Recovering ethanol from expired alcohol-containing products is a technically feasible and economically attractive strategy aligned with modern waste valorization and sustainability goals. Through engineered distillation, careful pre-sorting, and regulatory oversight, industries can transform expired stock into fuel, solvent, or sanitizer—extending the life of resources while protecting the environment.

Technical Article: Reclaiming Alcohol from Expired Products through Distillation

1. Overview

Reclaiming ethanol from expired products—including alcoholic beverages, cosmetics, pharmaceuticals, and cleaning solutions—is a viable industrial process that supports environmental sustainability and economic efficiency. The ethanol, being a stable compound, can be separated through controlled distillation and reused in industrial, fuel, or non-consumable applications.

2. Feedstock Types and Ethanol Content

| Product Category | Ethanol Range (% v/v) | Notes |

|---|---|---|

| Alcoholic Beverages | 4–50% | Beer, wine, spirits |

| Hand Sanitizers | 60–80% | Often denatured; requires post-processing |

| Perfumes and Colognes | 70–90% | Contains aromatic compounds |

| Mouthwash/Cosmetic Toners | 10–40% | May include menthol, glycerin |

| Pharmaceutical Syrups | 5–30% | Often requires pharmaceutical waste license |

| Herbal Extracts/Tinctures | 30–80% | Ethanol as solvent |

3. Technical Process

3.1 Pre-Processing

- Sorting and Segregation by ethanol concentration

- Unpacking & Crushing of containers if sealed (e.g., bottles, tubes)

- Filtration to remove solids, oils, and polymers

- pH Neutralization for acidic products

- Chemical Screening for toxic or reactive contents

3.2 Distillation Procedure

- Type: Fractional Distillation

- Apparatus: Stainless steel distillation column (with plates or packing)

- Heat Source: Direct steam injection or thermal oil system

- Control Variables:

- Boiling point of ethanol: 78.3°C

- Reflux ratio: Adjusted for desired purity

- Vacuum Pressure: Applied for heat-sensitive materials

- Condensation System: Shell-and-tube heat exchanger

- Ethanol Collection: Distillate collected between 70–85°C range

3.3 Post-Distillation Treatment

- Dehydration (molecular sieves for anhydrous output)

- Denaturing (if used for non-consumable purposes)

- Quality Control:

- GC-MS or HPLC to verify ethanol purity

- ASTM, USP, or EN standard conformity testing

- Storage:

- Stainless steel or HDPE tanks

- Grounding and vapor control measures

4. Output Specifications

| Product Use | Required Purity | Additives/Denaturants | Common Standards |

|---|---|---|---|

| Fuel Ethanol | ≥ 95% | Methanol, gasoline | ASTM D4806, EN 15376 |

| Industrial Solvent | 90–96% | MEK, IPA | ISO/ASTM compliant |

| Hand Sanitizer Base | 70–80% | Glycerin, hydrogen peroxide | WHO formulation or FDA |

| Laboratory/Pharma Grade | ≥ 96% | None (USP Grade) | USP, EP, JP |

| Cosmetic Base | ≥ 95% | Fragrance compounds | IFRA, EU Cosmetics Reg. |

5. Compliance & Safety

5.1 Legal and Regulatory

-

Licensing Required:

- Distillation permits (e.g., TTB in the US)

- Excise tax regulations for reclaimed ethanol

- Hazardous materials handling (e.g., REACH, EPA, MOH)

-

Traceability and Record-Keeping:

- Batch logs, destruction certificates, purity records

5.2 Safety Systems

- ATEX/NFPA-rated electrical and venting

- Explosion-proof zone classification

- VOC recovery or destruction units

- Fire suppression (foam/sprinkler systems)

6. Energy and Efficiency Metrics

- Typical Recovery Efficiency:

- ~90–95% ethanol from input material (depending on concentration)

- Energy Use:

- ~0.8–1.5 kWh per liter of recovered ethanol (depends on feedstock dilution)

- Carbon Savings:

- Up to 1.8 kg CO₂ avoided per liter compared to new ethanol production

7. Economic Considerations

| Variable | Range |

|---|---|

| Recovered ethanol price | $500–$1,200/ton |

| Processing cost per liter | $0.10–$0.30 |

| Disposal savings (per ton) | $100–$300 |

| Excise recovery (per liter) | Varies by country |

8. Limitations and Considerations

- Complex formulations may require multiple distillation passes

- Low alcohol content feedstocks (e.g., 4% beer) yield low return

- Toxic or pharmaceutical additives limit reuse without special treatment

- Cross-contamination risks require batch segregation and line cleaning

9. Conclusion

Distillation-based recovery of ethanol from expired or off-spec alcohol-containing products is a technically robust, economically viable, and environmentally responsible process. Through appropriate engineering, safety control, and compliance with legal standards, this method supports circular manufacturing, waste valorization, and resource recovery across multiple industries.

Would you like a schematic diagram of the distillation setup or flowchart of the full process as a visual addition?

Introduction

As sustainability and waste reduction become global priorities, innovative recycling methods are emerging across industries—including the alcohol industry. One such method is the recovery and reuse of alcohol from expired alcoholic beverages. Rather than discarding products that can no longer be sold, industrial distillation facilities can extract usable ethanol, turning waste into value.

This article explores the science, legality, and sustainability benefits of recycling alcohol from expired drinks, with a focus on industrial processes and their potential global impact.

1. The Concept: Alcohol Recovery through Distillation

Expired alcoholic beverages—such as beer, wine, and spirits—still contain significant amounts of ethanol. Although the flavor or packaging may deteriorate over time, the ethanol itself does not "expire." Through fractional distillation, alcohol can be separated from the water and other components in these drinks and recovered for various purposes.

This process involves:

- Heating the beverage until ethanol evaporates

- Capturing and cooling the vapor to condense it back into liquid

- Purifying and processing the alcohol depending on the target application

Recovered ethanol can be refined into neutral spirits, fuel alcohol, disinfectants, or industrial alcohol for laboratory or manufacturing use.

2. Industrial Applications and Case Studies

Several companies around the world already specialize in this kind of alcohol recycling:

-

Parallel Products (USA): Offers alcohol destruction and ethanol recovery services for expired or unsaleable beverages. The recovered alcohol is used in industrial and fuel applications.

-

Dynamic Recycling and EthanolRecycling.com: Provide secure destruction and ethanol reclamation, ensuring regulatory compliance and offering environmental benefits.

-

Encompass Technologies (USA): Reported a wave of “beer recycling” during the COVID-19 pandemic, where breweries distilled unsold or expired beer into hand sanitizer or whiskey, an effort known as the "Great Beer Rescue."

These practices reduce landfill waste, reclaim resources, and sometimes enable businesses to recover excise taxes on destroyed products.

3. Legal and Regulatory Considerations

While industrial distillation of expired alcoholic products is legal and regulated in many countries, home distillation is generally prohibited without proper licenses. In countries such as:

- United States: A federal permit is required for any distillation of alcohol, including for fuel or industrial purposes.

- Israel and EU Nations: Distillation is restricted and subject to licensing under tax and health regulations.

- Canada and UK: Similar restrictions apply, and enforcement is strict.

Unlicensed distillation can lead to fines, equipment seizure, and health risks due to improper purification.

4. Sustainability and Environmental Impact

Recycling alcohol from expired beverages has multiple environmental and economic benefits:

- Waste Reduction: Prevents tons of expired alcohol from entering landfills or sewer systems.

- Water Protection: Avoids chemical contamination of water systems from improper disposal.

- Carbon Offset: Replacing virgin ethanol production with recycled sources lowers carbon emissions.

- Circular Economy: Turns surplus or expired stock into valuable secondary products.

This practice aligns with global goals for circular industry, sustainable waste management, and climate resilience.

5. Potential for Wider Adoption

As beverage production scales globally and climate policy tightens, the ability to responsibly recycle alcohol will become more vital. Governments, beverage companies, and sustainability organizations can collaborate to:

- Create alcohol recycling hubs in beverage-producing regions

- Provide tax incentives for ethanol reclamation

- Encourage technological innovation in small-scale and mobile distillation systems

- Educate producers and regulators on the environmental importance of this process

Conclusion

Distilling alcohol from expired beverages represents a promising model for waste reduction, sustainability, and industrial efficiency. While home distillation remains illegal in most countries, licensed facilities are showing how expired alcohol can be transformed into new resources instead of waste.

As the world seeks innovative solutions to manage excess and reduce environmental harm, alcohol recycling through distillation offers a clear, clean, and powerful opportunity.

Abstract

This technical article explores the process of recovering ethanol from expired alcoholic beverages using controlled distillation. It details the chemical basis, industrial-scale processes, safety considerations, regulatory frameworks, and potential applications of the recovered ethanol. The method is a sustainable solution for managing expired alcohol stock in compliance with environmental and safety standards.

1. Background and Rationale

Alcoholic beverages have a limited shelf life due to the degradation of flavor compounds, oxidation, packaging deterioration, or microbial contamination. However, ethanol (C₂H₅OH), the primary active component, remains chemically stable over time. As such, expired beverages can be used as feedstock for ethanol recovery, enabling:

- Waste minimization

- Recovery of energy-dense compounds

- Conversion to industrial, fuel, or disinfectant-grade ethanol

- Tax recovery and regulatory compliance for producers

2. Ethanol Recovery Process

2.1 Feedstock Sources

- Beer (4–6% ABV)

- Wine (8–14% ABV)

- Spirits (30–50+% ABV)

- Mixed or spoiled beverages with ethanol content

These can be collected from manufacturers, wholesalers, or retailers with expired, damaged, or unsaleable stock.

2.2 Process Flow

Step 1: Pre-Treatment

- Filtration to remove solids and packaging residue

- pH adjustment and microbial deactivation if required

Step 2: Fractional Distillation

- Use of distillation columns (stainless steel or copper)

- Multi-stage heating to separate ethanol from water and volatiles

- Typical distillation temperature range: 78.3–100°C

- Reflux ratio control for purity

Step 3: Ethanol Collection

- Condensation via heat exchangers

- Storage in food-grade or industrial tanks

- Further dehydration (molecular sieves) for anhydrous ethanol, if required

Step 4: Denaturing (if non-consumable use)

- Ethanol may be denatured using methanol, isopropanol, or denatonium benzoate depending on local laws

3. Output Products and Applications

| Purity Level | Application | Notes |

|---|---|---|

| 70–90% | Surface disinfectants | Requires regulatory approval |

| 90–95% | Fuel-grade ethanol | Must meet ASTM D4806 or equivalent |

| 96–99% | Industrial solvents, chemical synthesis | Requires quality assurance and monitoring |

| 95–96.4% | Beverage-grade re-distillation | Only in permitted facilities |

4. Regulatory Framework

4.1 Licensing and Compliance

- US (TTB): Distillers must register as Alcohol Fuel Producers (AFP) or Industrial Alcohol Permit holders

- EU (Excise Directive 2008/118/EC): Recovery must be recorded and reported for tax adjustments

- Israel: Subject to approval by the Ministry of Health and the Israel Tax Authority

4.2 Safety Standards

- Explosion-proof equipment in accordance with ATEX (Europe) or NFPA (US)

- Vapor handling and condensation system

- Wastewater treatment for effluent containing sugars, acids, and yeast residues

5. Environmental and Economic Impact

5.1 Environmental Benefits

- Reduces landfill use and potential alcohol-related water contamination

- Enables carbon offset by substituting synthetic ethanol production

- Closed-loop cycle for beverage manufacturers and bottlers

5.2 Economic Benefits

- Excise tax recovery for destroyed beverages

- Revenue from ethanol resale

- Reduced disposal and environmental compliance costs

6. Technical Challenges

- High water content in beer and wine reduces yield per liter

- Contaminants or denatured stock may require additional purification

- Quality control is essential for safe reuse in consumer or fuel applications

7. Industrial Implementation Examples

- Parallel Products (USA) – Uses multi-column ethanol recovery systems for expired beverages

- Ethanol Recycling LLC – Specializes in converting out-of-date beer into industrial ethanol

- Brewery partnerships (COVID-19 response) – Converted unsellable beer into hand sanitizer

8. Conclusion

Distillation and ethanol recovery from expired alcoholic beverages is a proven, sustainable method for reclaiming valuable resources and reducing environmental impact. With proper licensing, engineering controls, and compliance, expired alcohol can be transformed into disinfectants, fuel, or industrial solvents—contributing to a circular economy in the beverage and biofuel industries.

Appendix: Sample Yield Estimates

| Beverage Type | ABV (%) | Input Volume | Expected Ethanol Yield |

|---|---|---|---|

| Beer | 5% | 1,000 L | ~50 L |

| Wine | 12% | 1,000 L | ~120 L |

| Vodka | 40% | 1,000 L | ~400 L |

Here is a regular article (non-technical tone, but still informative and professional) on the topic:

Reclaiming Alcohol from Expired Products: A Smart and Sustainable Solution

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

Every year, large amounts of alcohol-containing products go to waste. This includes expired beer, wine, spirits, perfumes, hand sanitizers, and even mouthwash. While the packaging or smell may have degraded, one valuable ingredient often remains unchanged: ethanol, also known as alcohol.

Instead of throwing these products away, companies around the world are beginning to reclaim and recycle the alcohol inside, turning waste into new usable resources. This process helps protect the environment, saves money, and supports a circular economy.

Why Alcohol Can Be Reused

Alcohol doesn’t spoil the same way food does. Even if the beverage or product is no longer safe or appealing to use, the alcohol itself remains stable. By heating and distilling the liquid, the alcohol can be separated, cleaned, and collected for use in other industries.

This reclaimed alcohol can then be used to make:

- Hand sanitizers

- Cleaning products

- Industrial solvents

- Fuel ethanol

- Even new spirits (in regulated facilities)

Which Products Can Be Recycled?

A wide range of expired or unsellable products can be processed to recover alcohol, including:

- Alcoholic drinks like beer, wine, and vodka

- Perfumes and colognes

- Medical and hygiene products like hand sanitizer and rubbing alcohol

- Mouthwashes and cosmetic sprays

- Herbal tinctures and syrups

Companies that specialize in this process sort these items, remove packaging, filter the liquids, and then use distillation to recover the alcohol.

The Recycling Process in Simple Terms

- Collect expired or returned alcohol-containing products

- Remove packaging and filter the liquid

- Heat the liquid to separate the alcohol

- Cool and collect the alcohol vapor into pure liquid

- Reuse the alcohol in new products or for fuel

This is typically done in large industrial facilities with the right licenses and safety systems.

Legal and Safety Rules

In most countries, only licensed companies are allowed to distill alcohol, even if it’s just for recycling. This is because alcohol is a regulated substance due to its potential for misuse and health risks. The process must also follow environmental and fire safety laws.

In places like the United States, Europe, and Israel, recycling alcohol is a legal practice—but it must be done properly, with the right permits and oversight.

Environmental and Economic Benefits

Recycling alcohol from expired products is good for the planet and the economy:

- Reduces waste: Less product goes to landfills

- Protects water systems: Prevents alcohol from entering sewers or rivers

- Saves money: Businesses recover alcohol instead of losing it

- Supports circular economy: Valuable materials are reused instead of discarded

- Creates jobs: New roles in logistics, recycling, and chemistry

Real-World Examples

During the COVID-19 pandemic, several distilleries in the U.S. and Europe started turning expired beer and wine into hand sanitizers to meet growing demand. Others used old products to create fuel or cleaning solutions, avoiding waste and helping communities.

Recycling companies like Parallel Products and Ethanol Recycling now work directly with retailers, breweries, and hospitals to recover alcohol from unsellable items.

Conclusion

Expired alcohol-based products may be past their prime, but the alcohol inside them is still valuable. Through smart recycling and modern distillation, it’s possible to recover and reuse this alcohol in useful and safe ways.

This is not only a practical solution—it’s a vision of a cleaner, smarter, and more responsible future.

Comments

Post a Comment