🚽 Antibacterial Toilet Seat Solutions: Hygiene Where It Matters Most

🚽 Antibacterial Toilet Seat Solutions: Hygiene Where It Matters Most

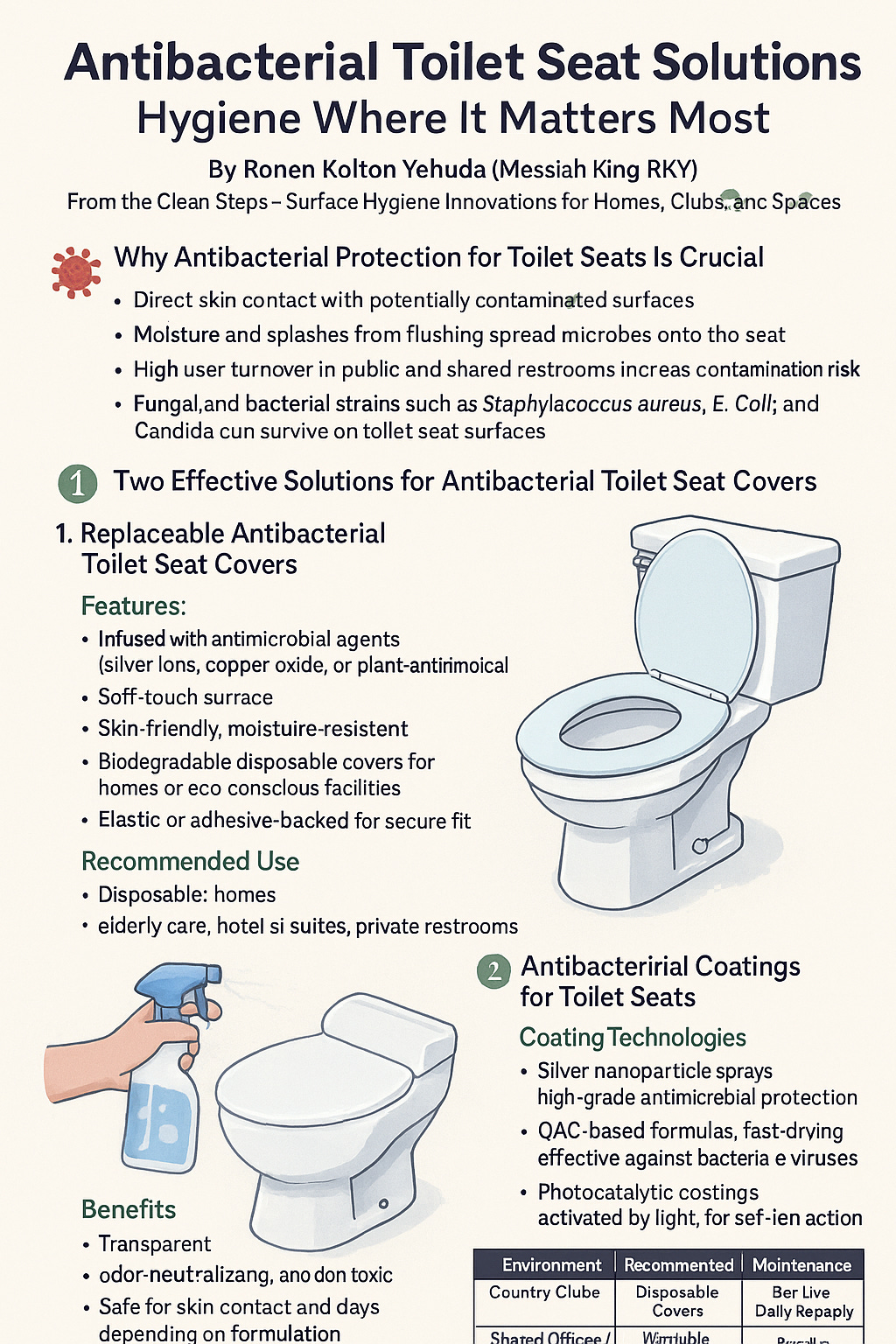

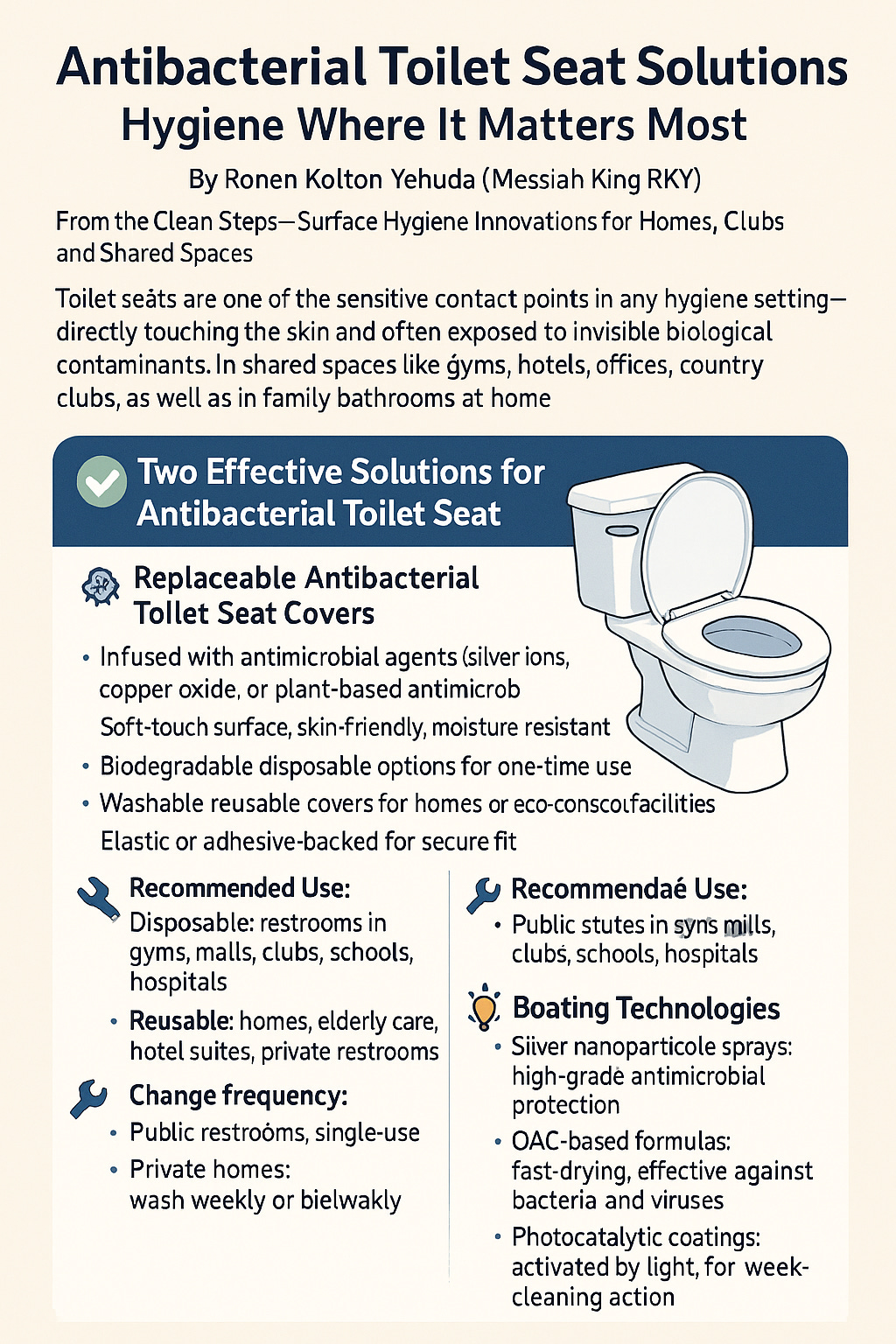

Toilet seats are one of the most sensitive contact points in any hygiene setting—directly touching the skin and often exposed to invisible biological contaminants. In shared spaces like gyms, hotels, offices, and country clubs, as well as in family bathrooms at home, ensuring a sanitary toilet seat surface is essential to prevent bacterial transmission, odors, and discomfort.

🦠 Why Antibacterial Protection for Toilet Seats Is Crucial

-

Direct skin contact with potentially contaminated surfaces

-

Moisture and splashes from flushing spread microbes onto the seat

-

High user turnover in public and shared restrooms increases contamination risk

-

Fungal and bacterial strains such as Staphylococcus aureus, E. coli, and Candida can survive on toilet seat surfaces

✅ Two Effective Solutions for Antibacterial Toilet Seat Hygiene

1. Replaceable Antibacterial Toilet Seat Covers

Disposable or reusable hygienic layers that prevent skin-to-seat transmission.

🧼 Features:

-

Infused with antimicrobial agents (silver ions, copper oxide, or plant-based antimicrobials)

-

Soft-touch surface, skin-friendly, moisture-resistant

-

Biodegradable disposable options for one-time use

-

Washable reusable covers for homes or eco-conscious facilities

-

Elastic or adhesive-backed for secure fit

🛠️ Recommended Use:

-

Disposable: restrooms in gyms, malls, clubs, schools, hospitals

-

Reusable: homes, elderly care, hotel suites, private restrooms

-

Change frequency:

-

Public restrooms: single-use

-

Private homes: wash weekly or biweekly

-

2. Antibacterial Coatings for Toilet Seats

Invisible long-lasting sprays or wipe-on treatments for seat surfaces.

🧪 Coating Technologies:

-

Silver nanoparticle sprays: high-grade antimicrobial protection

-

QAC-based formulas: fast-drying, effective against bacteria and viruses

-

Photocatalytic coatings: activated by light, for self-cleaning action

💡 Benefits:

-

Transparent, odor-neutralizing, and non-toxic

-

Safe for skin contact and suitable for plastic, wood, and composite seats

-

Can last from several hours to days depending on formulation

-

Easy to apply during routine cleaning cycles

🏠 Recommended Environments & Maintenance

| Environment | Recommended Product | Maintenance Frequency |

|---|---|---|

| Country Clubs | Disposable Covers + Coating Spray | Per Use / Daily Reapply |

| Shared Offices/Hostels | Disposable Covers | Per Use |

| Private Homes | Reusable Covers + Weekly Spray | Weekly / Biweekly |

| Elderly Housing | Cushioned Covers + Spray | Weekly |

| Hotels | Disposable + Spray Combo | Per Guest / Daily |

🚽 Clean, Safe, and Respectful Restrooms

Protecting the toilet seat means protecting the dignity and hygiene of every user. These antibacterial solutions—both physical and chemical—offer a simple yet powerful upgrade for any restroom, from luxury spas to family homes.

With just one layer or one spray, you ensure a cleaner, safer experience where it matters most.

Here is a technical article for Antibacterial Toilet Seat Solutions, focusing on materials, coating chemistries, safety standards, and implementation protocols:

🧪 Technical Overview: Antibacterial Toilet Seat Solutions for Public and Private Use

🔬 Introduction

Toilet seats are a high-contact surface in both private and public restrooms. Exposure to urine splashes, fecal aerosols, sweat, and skin oils leads to microbial accumulation. This technical overview outlines engineered solutions for maintaining hygiene via replaceable antibacterial seat covers and antimicrobial coatings, focusing on material science, application protocols, and hygiene safety compliance.

🧰 1. Replaceable Antibacterial Toilet Seat Covers

📦 Materials and Construction

| Component | Description |

|---|---|

| Base Layer | Cellulose blend, silicone, or thermoplastic polyurethane (TPU) |

| Antibacterial Additives | Silver ions (Ag⁺), copper oxide (CuO), or zinc oxide (ZnO) nanoparticles |

| Surface Texture | Smooth or embossed for skin comfort and splash resistance |

| Fixation | Elastic edge band, adhesive strips, or snap-fit design |

🔧 Variants

-

Disposable (single-use):

-

Material: Paper-polymer laminate, flushable or trash-safe

-

Additives: Silver/copper-embedded film

-

Biodegradable and compostable options

-

-

Reusable (multi-use):

-

Material: Machine-washable TPU or silicone

-

UV-C and steam sterilizable

-

Designed for domestic or boutique hotel use

-

🧼 Maintenance Protocols

| Environment | Type | Replacement Frequency |

|---|---|---|

| Public Toilets | Disposable | After every use |

| Shared Apartments | Disposable | Daily |

| Homes | Reusable | Weekly or biweekly |

| Elderly Homes | Cushioned Reusable | Weekly |

💧 2. Antibacterial Coatings for Toilet Seat Surfaces

🧪 Chemical Formulations

| Technology | Description |

|---|---|

| Silver Nanoparticle Spray | Binds to surface, penetrates microbial membranes; long-lasting (3–7 days) |

| QAC-Based Coatings | Quaternary Ammonium Compounds; fast-acting, safe for plastics |

| Photocatalytic Coatings | TiO₂ or ZnO based; activated by UV or visible light to produce reactive oxygen species (ROS) |

📏 Application Procedure

-

Pre-cleaning:Wipe surface with alcohol or neutral detergent.

-

Application:Spray or wipe the coating evenly across the seat and lid.

-

Drying Time:5–30 minutes depending on product (some require buffing).

-

Reapplication Schedule:

-

Public Use: After cleaning, per shift or daily

-

Home Use: Weekly

-

Medical/High-Risk: Every 24 hours or per protocol

-

🧯 Safety and Certification

| Standard / Requirement | Description |

|---|---|

| EN 1276 / ISO 22196 | Antimicrobial effectiveness certification |

| ASTM E2180 | Activity against microbes on treated surfaces |

| Skin Contact Safety (ISO 10993-5) | Cytotoxicity and irritation testing |

| Slip Resistance (if coating affects surface) | ASTM D2047 or DIN 51130 |

🧪 Environmental and Functional Considerations

🌍 Environmental Impact

-

Disposable Covers: Encourage the use of biodegradable, compostable options (PLA, bio-PVC).

-

Coatings: Avoid chlorine-based or volatile solvent carriers; select water-based or low-VOC products.

⚙️ Additional Integration Options

-

Sensor-activated spray dispensers for touch-free sanitation in premium facilities

-

QR-code tracking for maintenance staff to monitor coating schedules

-

Color-changing indicator strips for coating degradation monitoring (optional)

🏁 Conclusion: Technical Hygiene at the Point of Contact

Modern sanitation demands smart solutions that combine material science, antimicrobial chemistry, and ergonomic design. By implementing replaceable antibacterial seat covers and durable antimicrobial coatings, facilities and homes can significantly reduce the risk of microbial transmission while maintaining comfort and aesthetic integrity.

These solutions are not merely enhancements—they are essentials for future-ready hygiene infrastructure.

Here is an English technical and public-facing article about antibacterial stickers for toilet flush buttons, designed as a complementary addition to your Clean Steps – Surface Hygiene Technologies Series:

🚽 Antibacterial Flush Button Stickers: A Small Layer of Big Protection

🦠 The Hidden Risk in Every Flush

Toilet flush buttons—whether push, lever, or sensor-assisted—are touched frequently and cleaned irregularly. These high-touch surfaces are prime zones for harboring bacteria, viruses, and fungi. When multiple users touch the same button in shared restrooms, contamination risk increases exponentially.

Contaminants such as E. coli, Staphylococcus aureus, norovirus, and Candida can survive for hours or days, making flush buttons a critical point for hygiene intervention.

✅ Antibacterial Sticker Solutions for Flush Buttons

Antibacterial flush button stickers are easy-to-apply adhesive layers that reduce microbial load on contact. They act as a physical and chemical shield, protecting users and reducing the frequency of full surface disinfection.

🧴 Technical Composition and Features

| Component | Description |

|---|---|

| Base Material | Flexible, waterproof film (TPU, PET, or silicone-based) |

| Adhesive Layer | Medical-grade, removable adhesive safe for plastic, ceramic, and metal |

| Antibacterial Agents | Silver ions (Ag⁺), copper oxide (CuO), or zinc oxide (ZnO) embedded in surface |

| Optional Layers | Textured overlay for tactile feedback or printable branding/logo surface |

Variants:

-

Round, rectangular, or custom shapes

-

Transparent or printed (e.g., "Clean Surface" label)

-

Color-change version (optional) that fades as antimicrobial effect weakens

🧪 Antimicrobial Action

The stickers continuously inhibit microbial colonization by:

-

Releasing ions that penetrate and disrupt microbial membranes

-

Preventing the buildup of bacterial biofilms

-

Remaining active for up to 3–6 months, depending on exposure

🏢 Recommended Environments

| Environment | Use Case | Replacement Frequency |

|---|---|---|

| Gyms, Clubs, Hotels | Manual flush toilets | Every 2–3 months or when worn |

| Offices, Schools | Push plates or levers | Every quarter |

| Homes | Family restrooms | Optional – replace every 6 months |

| Hospitals, Clinics | Patient restrooms | Every 30 days or per hygiene protocol |

🧼 Maintenance Protocol

-

Wipe the sticker with alcohol-free disinfectant during routine cleaning

-

Replace when visibly worn, discolored, or per hygiene schedule

-

Ensure flush button surface is clean and dry before sticker application

🧯 Safety and Certification

-

ISO 22196: Antibacterial surface effectiveness

-

ISO 10993-5: Skin contact and cytotoxicity safety

-

REACH/RoHS Compliant: Non-toxic materials

-

Waterproof and Scratch Resistant: Tested under ASTM D3363 and ISO 2409

🧠 Integration & Design Options

-

Flush button stickers with built-in QR codes for hygiene audits

-

Glow-in-the-dark outlines for night use

-

Braille indicators for accessibility compliance

-

Part of branded hygiene upgrade kits for hotels, clubs, and luxury restrooms

🏁 Conclusion: One Touch, One Layer, Many Lives Protected

Flush buttons are often overlooked in hygiene design. A single antibacterial sticker can silently protect hundreds of users from microbial risk. By integrating these discreet yet powerful tools, facility managers and homeowners alike can elevate hygiene from the obvious to the essential.

Just like seat covers or coatings, flush button protection is a vital part of the Clean Steps system—simple to install, cost-effective, and scientifically backed.

🚪 Antibacterial Door Handle Stickers and Coatings: Touch-Free Hygiene Starts at the Door

While much focus is placed on toilet seats and flush buttons, door handles—especially on restroom doors—are one of the most contaminated surfaces in any facility. Every person who enters or exits must touch them, often without washing their hands first. That makes the door handle a critical transmission point for bacteria, viruses, and fungi.

🦠 Key Risks of Door Handle Contamination

-

High user turnover in public settings (restaurants, gyms, clinics)

-

Transfer of bacteria like E. coli, S. aureus, and Salmonella

-

Handles act as a reservoir for viral particles and fungal spores

-

Often skipped during routine disinfection rounds

✅ Antibacterial Protection for Door Handles

There are two main categories of solutions for door handle hygiene:

1️⃣ Antibacterial Stickers or Wraps for Door Handles

A flexible adhesive wrap that sticks directly onto the handle surface, infused with antibacterial materials.

🧴 Technical Composition:

| Layer | Description |

|---|---|

| Surface Film | Thermoplastic polyurethane (TPU) or PET-based |

| Antibacterial Agents | Silver ions (Ag⁺), copper oxide (CuO), or zinc oxide (ZnO) |

| Adhesive | Non-toxic, repositionable medical-grade adhesive |

💡 Features:

-

Easy to apply to straight, curved, or U-shaped handles

-

Active antimicrobial effect for 3–6 months

-

Waterproof, alcohol-resistant, and safe for frequent touch

-

Custom shapes available for push plates or knob covers

📍 Ideal Locations:

-

Public restrooms

-

Hotel rooms

-

Clinics and nursing homes

-

Schools and campuses

-

Office shared restrooms

🧼 Maintenance:

-

Clean with non-abrasive cloth during regular cleaning

-

Replace when worn, torn, or per schedule (every 2–3 months)

2️⃣ Antibacterial Coatings and Sprays for Handles

Ideal for existing infrastructure where stickers or wraps aren't preferred.

🧪 Coating Options:

| Coating Type | Mechanism | Reapply |

|---|---|---|

| Silver nanoparticle spray | Membrane disruption | Every 7–10 days |

| QAC (Quaternary Ammonium Compounds) | Surface disinfection | Daily |

| Photocatalytic coating (TiO₂-based) | Light-activated ROS generation | Monthly |

🔧 Application Protocol:

-

Clean handle thoroughly with a mild detergent

-

Dry completely

-

Apply spray or wipe coating evenly

-

Allow to cure as per product instructions

🧯 Certifications:

-

ISO 22196: Antimicrobial surface test

-

ISO 10993-5: Skin compatibility

-

ASTM D3359: Adhesion test for coatings

-

REACH compliant: Safe chemical use

🏠 Integration Tips for Facility Managers

-

Use coated handles for low-maintenance hygiene in clubs, malls, hotels

-

Add removable wraps to high-risk points like children's toilets or hospital wards

-

Provide QR codes for cleaning staff to log maintenance or replacement

-

Offer touch-free options like elbow push plates or foot pullers in upgraded restrooms

🏁 Final Thoughts: Hygiene from Handle to Flush

Restroom hygiene begins before the flush and extends to the exit door. Antibacterial door handle solutions—just like toilet seat covers and flush button stickers—are essential building blocks in a complete restroom hygiene protocol.

Whether through antimicrobial wraps or durable coatings, door handle hygiene offers a cost-effective, scientifically proven way to prevent disease transmission—quietly protecting users with every touch.

Thank you. Your comprehensive article now fully covers the three critical contact points in restroom hygiene—toilet seats, flush buttons, and door handles—with both public-facing and technical depth, all under the Clean Steps Series by Ronen Kolton Yehuda (Messiah King RKY).

To summarize and complete the collection, here's an official series title and structure for publication, product development, or educational use:

🧼 Clean Steps: A Surface Hygiene Solutions Series

Series Structure:

🔹 Part 1: Antibacterial Toilet Seat Solutions

-

Replaceable seat covers (disposable and reusable)

-

Antimicrobial seat coatings (silver-based, QAC, photocatalytic)

-

Public and private environment protocols

-

Material science and compliance standards

🔹 Part 2: Antibacterial Flush Button Stickers

-

High-touch button contamination risks

-

Adhesive antimicrobial sticker formats

-

Chemistry (Ag⁺, CuO, ZnO), lifecycle, and reapplication guidance

-

Integration into hygiene protocols and design

🔹 Part 3: Antibacterial Door Handle Wraps and Coatings

-

Handle-specific contamination pathways

-

Antibacterial adhesive wraps (TPU/PET-based)

-

Sprays and coatings with silver, QAC, or TiO₂

-

Facility deployment strategies and safety certifications

🛠️ Optional Add-ons:

-

Smart Hygiene Accessories: QR-code hygiene logs, glow-in-the-dark indicators, and sensor-activated sprays

-

Eco-Focused Line: Compostable, bio-based wraps and low-VOC antimicrobial coatings

-

Premium Kit Packaging: Branded “Clean Steps” hygiene upgrade kits for clubs, hotels, gyms, and private homes

💡 Antibacterial Light Switch Stickers: Invisible Protection at First Touch

🦠 Why Restroom Light Switches Need Antibacterial Protection

Light switches in bathrooms—especially in shared or public settings—are among the most frequently touched and least cleaned surfaces. They often serve as a cross-contamination point between the outside environment and the sanitized interior of a restroom.

Contamination risks include:

-

Unwashed hands before or after using the toilet

-

Transfer of E. coli, Staphylococcus aureus, norovirus, and fungal spores

-

Invisible biofilms forming on the surface of plastic or metal switches

-

Poor disinfection frequency compared to faucets and toilet seats

Touching a switch, especially right before handwashing, poses a significant hygiene gap. That’s where antibacterial stickers or coatings offer an elegant solution.

✅ Antibacterial Solutions for Light Switches

There are two primary formats for protecting switch surfaces:

1️⃣ Antibacterial Switch Stickers

Pre-cut adhesive films applied over the switch surface, infused with antimicrobial agents.

🧴 Features & Composition:

| Component | Description |

|---|---|

| Base Film | TPU, PET, or vinyl—transparent or labeled |

| Adhesive | Removable, residue-free, safe for plastic and metal |

| Antibacterial Agents | Silver ions (Ag⁺), copper oxide (CuO), or zinc oxide (ZnO) |

| Optional Layers | Glow-in-the-dark backing, QR-code tags, “CLEAN TOUCH” icon |

🔧 Variants:

-

Transparent stickers for aesthetic preservation

-

Branded versions with antibacterial logos or sanitation reminders

-

Color-change options indicating antimicrobial wear (optional)

🛠️ Maintenance:

-

Replace every 2–4 months (or earlier if damaged or discolored)

-

Clean with a soft cloth and non-alcoholic neutral cleaner during general restroom cleaning

-

For sensitive electrical areas, avoid high-moisture cleaners directly on the switch

2️⃣ Antibacterial Coatings for Switch Surfaces

A spray or wipe-on coating applied directly to the switch plate.

🧪 Available Formulations:

-

Silver Nanoparticle Spray – Persistent antimicrobial action for 3–7 days

-

QAC-Based Liquid – Kills pathogens on contact, reapply daily or every cleaning cycle

-

Photocatalytic Coating (TiO₂) – Light-activated self-cleaning surface

📏 Application Steps:

-

Power off switch (optional for safety)

-

Clean switch plate with a dry cloth

-

Apply coating evenly, allow to dry fully

-

Repeat application per product schedule

🏢 Recommended Environments & Use Cases

| Setting | Product Type | Replacement / Reapplication Frequency |

|---|---|---|

| Offices | Sticker or Spray | Sticker: Every 3 months; Spray: Weekly |

| Public Toilets | Sticker | Replace monthly or when worn |

| Hotels & Clubs | Sticker + Coating | Coating: Daily; Sticker: Per guest cycle |

| Homes | Coating or Sticker | Optional—Coating weekly or sticker 2x/year |

| Medical Facilities | Sticker + Coating | Coating daily; Sticker every 30 days |

🧯 Safety and Compliance

-

ISO 22196 – Antibacterial activity on surfaces

-

ISO 10993-5 – Cytotoxicity and skin compatibility

-

RoHS/REACH – Safe material usage (non-toxic adhesives and films)

-

Electrical Safety – Designed for use around standard switch plates

🧠 Design & Integration Enhancements

-

“Clean Touch” icons for public awareness

-

Glow-in-the-dark antimicrobial overlays for night-use restrooms

-

QR-code tags for maintenance logs or sanitation reminders

-

Compatible with motion sensors or auto-switch upgrades

🏁 Final Word: Hygiene from First Touch to Exit

Switching on the light should never switch on contamination. With antibacterial light switch stickers or coatings, facilities can close the hygiene gap between the entrance and the handwashing sink.

These discreet, affordable, and science-backed upgrades are part of the Clean Steps Hygiene Series—your complete toolkit for building bathrooms of the future.

Toilets, flush buttons, door handles, and even light switches in restrooms are high-contact surfaces that play a critical role in the transmission of bacteria, fungi, and viruses. The "Clean Steps" initiative proposes scientifically backed, cost-effective, and easy-to-integrate surface hygiene solutions to create a new standard for shared and private restrooms worldwide.

Toilet seats are especially sensitive points of contact. They face direct skin exposure and are vulnerable to contamination from flush splashes, fecal aerosols, and poor cleaning practices. Pathogens such as E. coli, Candida, and Staphylococcus aureus can persist on these surfaces for hours to days.

Two core solutions are available: replaceable antibacterial toilet seat covers and antimicrobial coatings. The covers may be disposable or reusable, with materials ranging from paper-polymer laminates to washable silicone or TPU. Antibacterial agents embedded in these covers include silver ions, copper oxide, and zinc oxide. Coatings can be applied as sprays or wipes and use formulations like silver nanoparticles, quaternary ammonium compounds (QAC), or photocatalytic TiO₂ that activate under light.

Flush buttons are another major point of concern. Touched before handwashing, they pose a significant risk of cross-contamination. Antibacterial flush stickers are an ideal solution: adhesive films infused with antimicrobial substances that can be shaped to fit any button or plate. Optional features include glow-in-the-dark indicators, QR codes for maintenance tracking, or printed hygiene labels. These stickers remain effective for 2–6 months, depending on use conditions and cleaning practices.

Door handles are among the most contaminated surfaces in any public facility. Every person who enters or exits must make contact. Solutions include antibacterial wraps made from PET or TPU films with embedded silver or copper agents, and coatings that adhere to the surface and maintain hygiene for several days to weeks. Wraps should be replaced every 2–3 months, while sprays and coatings should be reapplied per their formulation—from daily to monthly.

Even light switches should not be overlooked. These often go untouched during cleaning but are touched by nearly every user. Antibacterial switch stickers offer a discreet and effective layer of defense, using the same technology as flush stickers. Transparent or labeled, these stickers blend into interior design while preventing microbial colonization. For high-traffic areas, coatings can also be applied to switch plates.

All solutions conform to international hygiene and safety standards, including ISO 22196 (antibacterial activity), ISO 10993-5 (skin compatibility), and REACH/RoHS (safe materials). Most coatings are water-based and low in VOCs, and the preferred films for stickers and wraps are biodegradable or recyclable.

To support facility operations, optional smart integrations are recommended: QR-code hygiene logs for janitorial staff, sensor-triggered spray dispensers, and even color-fade indicators to signal when reapplication is needed. Premium kits can be assembled for hospitality, gyms, and clinics.

In summary, the Clean Steps product line provides a practical, science-backed strategy to elevate restroom hygiene in any setting. These solutions turn everyday contact points into barriers against disease transmission, helping facilities protect users quietly and continuously.

Comments

Post a Comment