Clean Steps: Kitchen & Dining Hygiene – Antibacterial Solutions for Where We Cook, Prep, and Eat

🧼 Clean Steps: Kitchen & Dining Hygiene – Antibacterial Solutions for Where We Cook, Prep, and Eat

🍽️ Introduction: Surfaces That Feed Us Deserve Better Protection

Kitchens and dining tables are central to life. They’re where we prepare meals, gather with others, and share food. But these spaces are also some of the most vulnerable to bacteria, spills, and contamination—especially when cooking for children, the elderly, or in shared environments like cafés, schools, or dorms.

Clean Steps presents antibacterial solutions that make these spaces not just cleaner—but safer, smarter, and easier to maintain.

✅ Three Easy Ways to Protect Kitchen and Dining Surfaces

Unlike bathrooms, kitchen surfaces are exposed to oils, food scraps, and skin contact. This means we need food-safe, water-resistant, and durable hygiene systems that are gentle on people and strong against bacteria.

1. Antibacterial Coatings for Kitchen Floors

Whether in a restaurant or home, kitchen floors see everything—grease, water, crumbs, and foot traffic. Specialized floor coatings help seal the surface, resist slipping, and stop microbes from taking hold.

Benefits:

-

Keeps floors cleaner, longer

-

Prevents slippery spots from spills

-

Safe even when food is dropped and picked up

-

Lasts from several days to a few weeks depending on use

Where to Use:

-

Home kitchens

-

Open kitchens in shared housing

-

Cafés and restaurants

-

School and hospital kitchen floors

2. Safe Sprays for Counters and Food Zones

We touch countertops constantly while preparing meals. With the right antibacterial spray, you can clean and disinfect in one quick wipe—without needing harsh chemicals or rinsing afterward.

Great For:

-

Cutting boards, prep tables, and kitchen islands

-

Sink edges and fridge handles

-

Stone, wood, metal, or plastic surfaces

Features:

-

Food-grade safe: no rinse needed

-

Fast-acting: kills most germs in under a minute

-

Available in natural versions (citric or lactic acid, silver, vinegar)

-

Great for homes with kids or pets

3. Dining Table Hygiene – Before the First Bite

Dining tables are more than furniture—they’re food stages. When shared by multiple people, used by children, or set in restaurants, hygiene should start before the meal does.

Two Solutions:

Best Use:

| Setting | Solution | Frequency |

|---|---|---|

| Family Tables | Natural or silver-based spray | After each meal |

| Restaurants | Fast-drying QAC spray | After every guest |

| Elderly Care | Hypoallergenic spray or coating | Before/after meals |

| Shared Kitchens | Table coating + daily spray | Spray daily, coat weekly |

🧯 Safety First: What to Look for in Products

All sprays and coatings for kitchen and table use should meet the following:

-

✅ Food contact safety (FDA / EU certified)

-

✅ Antibacterial effectiveness (ISO 22196 / EN 1276)

-

✅ Safe for hands and skin (ISO 10993-5)

-

✅ Slip-resistant for floor use (ASTM or DIN tested)

-

✅ VOC-free (safe to inhale, especially around children or pets)

🌱 Choose Eco-Friendly Hygiene

The best hygiene solutions are also smart for the planet:

-

Biodegradable formulas

-

Refillable spray bottles

-

No chlorine or harsh solvents

-

Low environmental impact with frequent use

🧼 Conclusion: Clean Surfaces = Safer Meals

From kitchen floors to dining tables, every clean surface is a small act of care. With the right sprays and coatings, you don’t just remove germs—you make your space more respectful, more welcoming, and more prepared for the people you love or serve.

Hygiene doesn’t need to be hard. It just needs to be part of the recipe.

🍽️ Clean Steps Expansion: Antibacterial Solutions for Eating Tables and Dining Surfaces

🍴 Where We Eat Deserves Where We Clean Best

Dining tables are intimate, high-contact surfaces where food is served, hands rest, and people of all ages gather—often without noticing what was on the surface before. From family meals to restaurant service, shared dorm tables to elderly care dining halls, these surfaces must be clean not just for appearance but for food safety and health protection.

Antibacterial table surface solutions ensure that every bite begins on a safe surface.

✅ Two Simple Yet Essential Solutions for Dining Hygiene

1. Food-Safe Antibacterial Tabletop Sprays

These are quick-acting, non-toxic sprays applied to dining surfaces before or after meals. Unlike standard cleaners, they are certified for direct food contact and contain safe antimicrobial agents that prevent bacterial buildup on tabletops.

Features:

-

🧴 Non-toxic and safe for cutlery, hands, and food residue

-

💧 Leaves no sticky film or residue

-

🌿 Available in natural formulations (citric acid, vinegar, plant enzymes)

-

🧼 Cleans and disinfects simultaneously

-

🧒 Hypoallergenic versions for children's eating spaces

Best For:

-

Home dining tables

-

School lunchrooms

-

Restaurant table reset between guests

-

Elderly housing meal tables

-

Cafeteria and hospital dining areas

Spray Recommendations by Environment:

| Setting | Product Type | Application Frequency |

|---|---|---|

| Family Dining Table | Natural spray (e.g., vinegar + silver ion) | After each meal |

| School Tables | Alcohol-free disinfectant spray | Between groups / daily |

| Restaurants | Fast-drying QAC-based spray | Between guests |

| Elderly Centers | Hypoallergenic spray | Before/after every meal |

| Outdoor Tables | UV-stable antimicrobial spray | Daily or as needed |

2. Antibacterial Tabletop Coatings

For restaurants, cafeterias, or shared spaces where continuous use is expected, invisible antibacterial coatings offer long-term protection against microbes.

How It Works:

-

Applied as a liquid or wipe-on formula

-

Binds to wood, plastic, laminate, metal, or composite tabletops

-

Prevents bacterial colonization between cleanings

-

Some coatings last days to weeks with proper use

Technologies:

-

Silver Nanoparticle Coatings: Safe and durable for food zones

-

Photocatalytic Coatings (TiO₂): Self-activating with daylight

-

Enzyme-Activated Sprays: Break down organic contamination

Ideal Use Cases:

-

Fast-food or casual dining outlets

-

Canteens and buffet halls

-

Shared kitchen islands in co-living or hostels

-

Event venues and pop-up dining

🛠️ Technical Safety and Standards for Eating Surfaces

| Standard | Description |

|---|---|

| EN 1276 / ISO 22196 | Antibacterial efficacy (non-porous dining surfaces) |

| ISO 10993-5 | Cytotoxicity safety for skin and food contact |

| FDA CFR 178.1010 | Approved food-contact surface sanitizers (US) |

| EU Regulation 1935/2004 | Food-contact surface regulation (Europe) |

| VOC-Free Labeling | For use around children and sensitive users |

🌿 Sustainability and Material Choices

Choose products that:

-

Are free from triclosan, chlorine, and formaldehyde

-

Use plant-based or biodegradable antimicrobial agents when possible

-

Offer refillable spray bottles or bulk options for large dining facilities

-

Avoid plastic buildup on natural surfaces (use breathable coatings for wood)

🧼 Final Bite: Hygiene Makes the Table

Clean plates begin on clean tables. Whether it’s a five-star restaurant, a school lunch bench, or your family dining nook, the table is where hygiene meets humanity. With safe, effective antibacterial sprays or invisible coatings, you create a dining space that respects the food—and the people.

These aren't just table cleaners—they’re trust builders.

🧪 Technical Overview: Antibacterial Surface Solutions for Kitchens, Eating Tables, and Food Zones

🔬 Introduction

In food-prep, cooking, and dining zones, microbial contamination presents a direct health risk. Surfaces exposed to heat, oils, food waste, and frequent human contact require durable, food-safe, and certified antimicrobial treatment. This technical article provides an in-depth analysis of materials, formulations, safety protocols, and coating technologies applied to:

-

Kitchen floors

-

Food-preparation surfaces

-

Dining tables

-

High-touch kitchen and eating zones

1️⃣ Antibacterial Coatings for Kitchen Floors

📦 Material Compatibility

| Surface | Recommended Coating Type |

|---|---|

| Vinyl / PVC | QAC or nanoparticle-based waterborne coatings |

| Concrete | Epoxy base + antimicrobial topcoat |

| Ceramic Tile | Photocatalytic spray or polymer sealant |

| Stainless Steel Flooring (industrial) | QAC-based fast-dry sprays |

| Natural Stone | Breathable solvent-free silver-based formulas |

🧪 Coating Composition

| Compound | Function |

|---|---|

| Silver Ions (Ag⁺) | Continuous microbe suppression through ion release |

| QACs (Quaternary Ammonium Compounds) | Fast microbial lysis; ideal for short-term protection |

| TiO₂ (Photocatalytic Titanium Dioxide) | Activates with light to produce reactive oxygen species |

| Zinc Oxide (ZnO) | Effective antifungal for warm, oily zones |

📏 Application Guidelines

-

Surface prep: Degrease, clean with neutral detergent, and dry fully.

-

Application: Spray, fog, or roll; avoid pooling.

-

Dry time: 10–30 minutes depending on ambient humidity.

-

Reapplication schedule:

-

Commercial kitchens: Every 5–7 days

-

Home kitchens: Every 14–30 days

-

Heavy-duty zones: After major spills or floor stripping

-

2️⃣ Antibacterial Sprays for Countertops and Food Prep Zones

🧴 Approved Ingredients for Food Contact Surfaces

| Active Ingredient | Safety Certification |

|---|---|

| Ethanol 70% (with food-grade stabilizers) | FDA CFR 178.1010 / EU 1935/2004 |

| Silver citrate | ISO 10993-5, food-safe & non-toxic |

| Citric acid | Plant-based sanitizer; biodegradable |

| Lactic acid | Non-residue antimicrobial, GRAS-listed |

| Hypochlorous acid (HOCl) | Human-safe, child-safe, fast evaporating |

🧠 Key Safety Attributes:

-

No rinse needed on food-contact areas (must be explicitly certified)

-

Fast-evaporating and streak-free for visible surfaces

-

Safe on skin (ISO 10993-10) and inhalation safe (VOC-free, fragrance-free variants)

3️⃣ Antibacterial Coatings for Eating Tables & Dining Surfaces

🪑 Surface Compatibility

| Table Material | Coating Compatibility |

|---|---|

| Laminated Wood | Water-based QAC or enzyme-coating |

| Solid Wood | Silver ion coating; avoid solvent-heavy sprays |

| Stainless Steel | QAC or nanoparticle spray |

| Plastic & Resin | TiO₂, enzyme-based, or QAC-compatible |

| Composite or Epoxy | Any food-safe certified spray |

🧪 Coating Technologies

| Coating Type | Description | Reapplication |

|---|---|---|

| Silver Nanoparticle Spray | Microscopic Ag⁺ ions bind to bacteria and fungi | 3–7 days |

| Enzyme-Activated Spray | Breaks down biofilm and organic residues | 12–24 hrs |

| Photocatalytic Coating (TiO₂) | Self-cleaning in presence of light | Weekly |

| Natural Acid Sprays (Citric, Vinegar, Lactic) | Mild, effective; best for home use | After each meal |

🔧 Application & Maintenance Protocols

🧽 Cleaning Protocol Prior to Coating/Spraying:

-

Wipe away all organic residue (food, oil, biofilm)

-

Use a neutral pH cleaner or alcohol

-

Dry surface completely to allow full coating adhesion

🛠️ Spray/Coating Maintenance Frequencies (Summary)

| Zone | Spray Type | Frequency |

|---|---|---|

| Restaurant Counter | QAC Spray | Hourly or after service |

| Home Kitchen Counter | Silver-based Spray | After each cooking session |

| Buffet Dining Tables | Enzyme Spray + Coating | Every 2 hours |

| School Lunch Tables | Non-alcohol, QAC-free Spray | Between meals |

| Elderly Dining Area | Hypoallergenic Spray | Before/after every meal |

🧯 Certifications & Standards Matrix

| Standard | Purpose |

|---|---|

| EN 1276 / ISO 22196 | Surface antimicrobial activity test |

| ASTM E2180 | Long-term microbial inhibition on treated plastics |

| ISO 10993-5 | Cytotoxicity for human skin safety |

| FDA CFR 178.1010 | Sanitizing agents for food-contact surfaces |

| EU Regulation 1935/2004 | Compliance for surfaces in contact with food |

| ASTM D2047 / DIN 51130 | Slip resistance for wet kitchen floors |

🌱 Environmental Considerations

-

Preferred: water-based, biodegradable, VOC-free, non-chlorinated sprays

-

Avoid: bleach-based sprays on food-contact zones, solvent-heavy products

-

Recyclable packaging: encourage bulk refill stations for food service operations

-

Sustainable materials: opt for enzyme and silver coatings over harsh chemical alternatives

✅ Summary: Engineering Cleanliness Where Food Lives

This technical framework enables safe and consistent application of antibacterial surface solutions in critical food environments. By adhering to certified chemical compositions, appropriate surface-matching, and reapplication protocols, hygiene becomes a scientifically enforced standard—not guesswork.

From kitchen tiles to school dining tables, antibacterial treatment is now part of the foundation of healthy living.

🧼 Clean Steps Finder: Choosing the Right Antibacterial Solutions for Kitchen and Dining Hygiene

By Ronen Kolton Yehuda (Messiah King RKY)

From the Clean Steps Series – Surface Hygiene Innovations for Homes, Hospitality, and Shared Facilities

🧭 Introduction: Fast Match for Surfaces That Matter

Looking for the right antibacterial solution for your kitchen floor, prep counter, or dining table? This Clean Steps finder helps you choose quickly and smartly—based on your space, surface type, and frequency of use.

🔍 Solution Finder by Zone

🍳 Kitchen Floors

| Setting | Product Type | Features | Reapply |

|---|---|---|---|

| Home | Water-based food-safe floor coating | Slip-resistant, grease-repellent | Every 2–4 weeks |

| Restaurant | Epoxy or nanoparticle coating | Oilproof, hospital-grade hygiene | Weekly |

| Shared Housing | Antibacterial mats or spray sealants | Removable, renter-safe | Weekly or as needed |

| Elderly Kitchens | Slip-safe silver-based coating | Antifungal, low odor | Biweekly |

🧼 Counters & Food Prep Zones

| Surface | Product Type | Safety | Application |

|---|---|---|---|

| Granite / Marble | Citric or lactic acid spray | No rinse, child-safe | After each prep |

| Stainless Steel | QAC spray (fast dry) | FDA-approved | Hourly or per shift |

| Wood / Butcher Block | Silver citrate or enzyme spray | Plant-based options available | After each use |

| Mixed Use (schools/dorms) | Alcohol-free surface spray | Hypoallergenic | 2–3x daily |

🍽️ Dining Tables

| Setting | Product | Type | Frequency |

|---|---|---|---|

| Family Table | Vinegar + silver-based spray | Natural & food-safe | After each meal |

| Restaurants | Fast-drying QAC spray | Commercial certified | After every guest |

| School Lunchroom | Non-alcohol disinfectant | Kid-safe, fragrance-free | Between seatings |

| Elderly Centers | Hypoallergenic coating + spray | Long-lasting + gentle | Spray daily, coat weekly |

| Outdoor Tables | UV-stable antimicrobial spray | For metal, plastic, wood | Daily or after weather exposure |

✅ Certified Product Attributes to Look For

-

EN 1276 / ISO 22196: Verified antibacterial effectiveness

-

ISO 10993-5: Safe for skin and food contact

-

FDA GRAS / CFR 178.1010: Approved for food-prep surfaces

-

VOC-Free: Safe for kids, pets, and enclosed spaces

-

ASTM D2047 / DIN 51130: Anti-slip on wet kitchen floors

🛍️ Top Antibacterial Product Types

-

Silver nanoparticle sprays: Durable, skin-safe, and food-zone approved

-

QAC-based sprays: Fast, effective for commercial use

-

Natural acid sprays (citric, vinegar, lactic): Gentle, rinse-free, biodegradable

-

Photocatalytic coatings: Ideal for daylight-rich areas

-

Enzyme-activated cleaners: Organic breakdown of grease and bacteria

🌱 Eco & Safety Tips

-

Choose biodegradable, chlorine-free, and refillable packaging

-

Avoid harsh solvents in family or food zones

-

For daily use, prefer fragrance-free, non-alcoholic, and skin-safe formulas

🧼 Final Reminder: Hygiene is a Habit, Not Just a Product

Clean kitchens, safe prep zones, and sanitized tables are not luxuries—they are standards of care. With the right product matched to the right surface and frequency, maintaining these spaces becomes easy, reliable, and responsible.

🧪 Technical Overview: Clean Steps Product Selection Guide for Kitchen Floors, Food Zones, and Dining Surfaces

By Ronen Kolton Yehuda (Messiah King RKY)

From the Clean Steps Series – Technical Surface Hygiene Protocols for Homes, Restaurants, and Shared Kitchens

🔬 Introduction: Precision Matching of Surface Hygiene to Use Case

Effective antibacterial hygiene for food-related environments depends on precise material matching, regulatory compliance, and context-specific application protocols. This document outlines a product selection and application framework for maintaining antimicrobial protection across kitchen floors, food-prep counters, and dining surfaces in homes, restaurants, institutions, and shared spaces.

1️⃣ Antibacterial Coatings for Kitchen Flooring

📦 Material Compatibility Matrix

| Surface Type | Recommended Coating | Notes |

|---|---|---|

| Vinyl / PVC | Water-based QAC or Ag⁺ coating | Durable, quick dry |

| Ceramic Tile | TiO₂ or epoxy hybrid | Slip-safe, stain-resistant |

| Concrete | Epoxy resin base + antimicrobial topcoat | For commercial kitchens |

| Stone / Marble | VOC-free silver nanoparticle spray | Avoid acid-based cleaners |

| Stainless Steel (floor-grade) | QAC fast-dry + slip additive | Industrial kitchens |

🧪 Formulations

-

Silver Ions (Ag⁺): Persistent bacteriostatic layer; food-safe

-

TiO₂: Photocatalytic; requires UV/visible light

-

Zinc Oxide (ZnO): Antifungal, stable in oils

-

QACs: Short-term but rapid microbial lysis

-

Epoxy Blends: Combine durability with antimicrobial polymer bonding

🛠️ Application Guidelines

-

Surface Preparation: Degrease, neutral-pH wash, dry

-

Application Method: Low-pressure sprayer, roller, or fogger

-

Cure Time: 20–30 min (ambient dry); 24h full-set for foot traffic

-

Reapplication Interval:

-

Commercial: Every 5–7 days

-

Residential: Every 14–30 days

-

Heavy use: After spills, degreasing, or abrasion

-

2️⃣ Antibacterial Sprays for Food Contact Zones (Counters, Sinks, Islands)

🧴 Approved Actives for Food Contact Use

| Ingredient | Certification | Key Properties |

|---|---|---|

| Ethanol 70% (food-safe) | FDA CFR 178.1010 | Rapid evaporation, no residue |

| Silver citrate | ISO 10993-5 | Broad-spectrum antimicrobial |

| Citric acid | EU 1935/2004 | Biodegradable, organic-approved |

| Hypochlorous Acid (HOCl) | GRAS / EPA | Human-safe, ultra-fast acting |

| Lactic acid | GRAS | Non-corrosive, residue-free |

📏 Application Protocol

-

Pre-clean surface of organic matter

-

Spray directly (5–10 ml per 0.1 m²)

-

Allow to dwell for 60 seconds

-

Optional wipe for visible zones

-

Repeat every 2–6 hours depending on usage

3️⃣ Dining Surface Coatings & Sprays (Tables, Trays, Shared Counters)

🪑 Coating Compatibility by Material

| Material | Compatible Technology |

|---|---|

| Laminated Wood | Water-based QAC or TiO₂ |

| Solid Wood | Silver citrate or enzyme-based |

| Stainless Steel | QAC / Ag⁺ spray |

| Plastic (HDPE, resin) | TiO₂ or QAC |

| Composite or Epoxy | Universal (avoid acid-based) |

🧪 Spray / Coating Types

| Type | Description | Efficacy Duration |

|---|---|---|

| Silver-based Spray | Long-acting (Ag⁺ diffusion) | 3–7 days |

| Enzyme Cleaner | Breaks biofilm + sanitizes | 12–24 hrs |

| Photocatalytic Spray | Light-activated, self-cleaning | Weekly |

| Citric/Lactic Acid | Short-term, food-safe | After each meal |

| Alcohol-Free QAC | For schools/elderly centers | Multiple uses per day |

4️⃣ Certification and Safety Compliance

| Standard | Description |

|---|---|

| EN 1276 / ISO 22196 | Antibacterial activity on hard surfaces |

| ISO 10993-5 | Skin and food-contact cytotoxicity |

| ASTM D2047 / DIN 51130 | Slip resistance for wet flooring |

| FDA CFR 178.1010 | Approved for food-contact surface sanitizers |

| EU 1935/2004 | Food contact safety in Europe |

| ASTM E2180 | Long-term antimicrobial surface activity |

5️⃣ Technical Recommendations by Use Case

| Zone | Preferred Product | Maintenance Interval |

|---|---|---|

| Home Kitchens | Silver-based spray + waterborne floor coat | Daily spray, coat biweekly |

| Restaurants | QAC spray + epoxy antimicrobial coating | Spray hourly, coat weekly |

| Elderly Dining Areas | Hypoallergenic spray + Ag⁺ coating | Before/after each meal |

| Shared Housing | Table coating + surface spray | Coat weekly, spray daily |

| School Lunch Rooms | Alcohol-free QAC spray | Between meals |

| Cafeterias/Buffets | Enzyme + TiO₂ coating | Spray every 2 hrs, coat weekly |

🌱 Environmental and Health Considerations

Preferred:

-

VOC-free, biodegradable, hypoallergenic formulations

-

Plant-based acids or enzyme systems

-

Refillable containers, recyclable packaging

Avoid:

-

Chlorine-based or solvent-heavy disinfectants on food zones

-

Persistent film-forming agents on wooden tables

-

Fragranced sprays in dining/kitchen areas with respiratory risk

✅ Conclusion: Data-Driven Cleanliness for Critical Surfaces

The Clean Steps technical protocol aligns hygiene practices with certified materials, safe chemical design, and practical reapplication schedules. For kitchens and dining zones, these solutions are not supplementary—they are foundational infrastructure for food safety, public trust, and operational excellence.

🧼 Clean Steps Finder: The Right Antibacterial Solutions for Kitchens and Dining Surfaces

By Ronen Kolton Yehuda (Messiah King RKY)

From the Clean Steps Series – Hygiene Innovations for Every Space You Cook and Eat

🍽️ Introduction: Clean Where It Counts

Our kitchens and dining tables are where meals begin—and where health risks can quietly grow. Crumbs, grease, spills, and shared contact make these areas prime spots for bacteria to spread. That’s why Clean Steps created this easy guide to help you pick the right antibacterial products for every corner of your food space.

Whether you're a home cook, café manager, or school kitchen supervisor—this article helps you find smart, safe, and sustainable hygiene solutions.

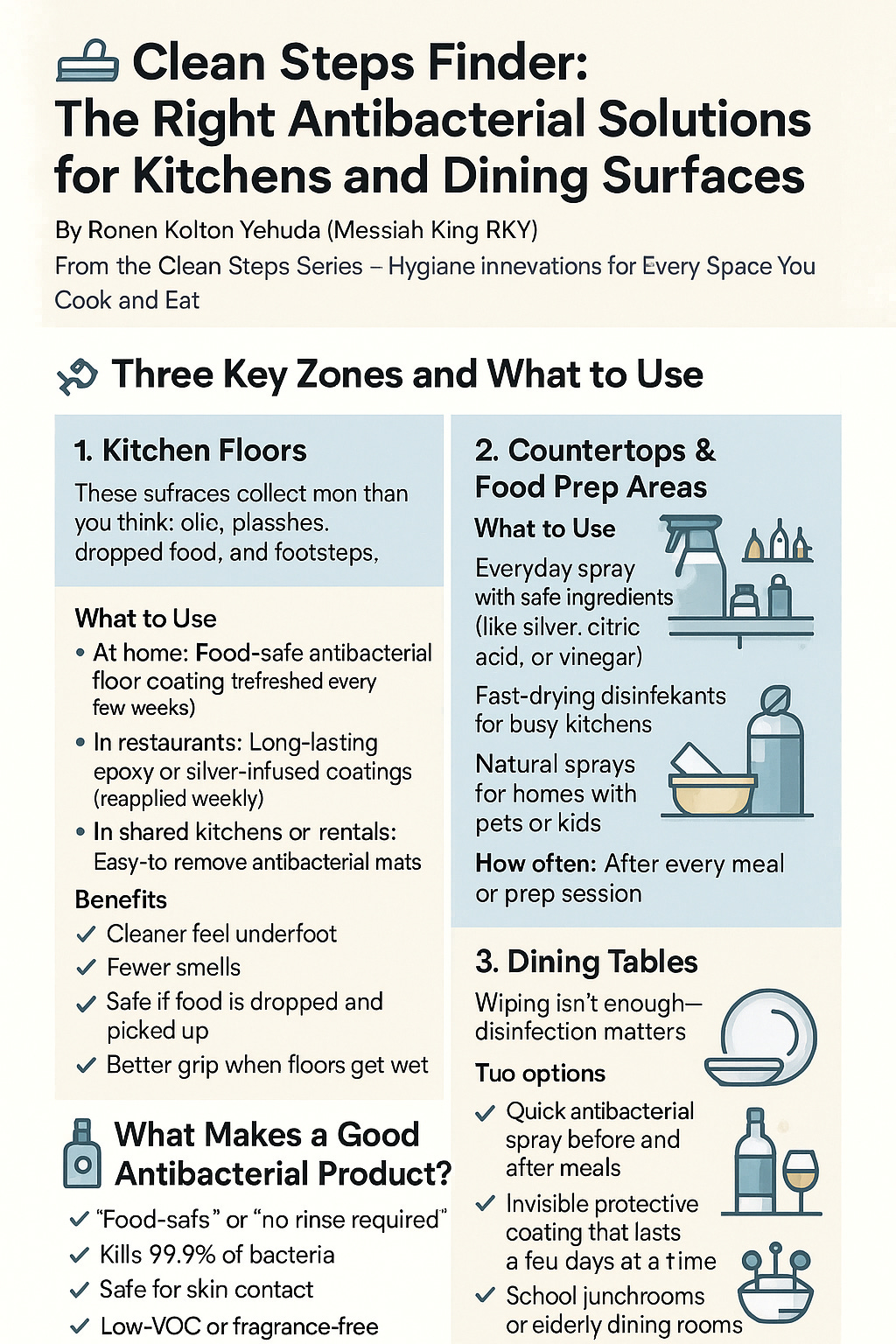

✅ Three Key Zones and What to Use

1. Kitchen Floors

These surfaces collect more than you think: oils, splashes, dropped food, and constant footsteps. A good floor treatment should make them safer, cleaner, and less slippery.

What to Use:

-

At home: Food-safe antibacterial floor coating (refreshed every few weeks)

-

In restaurants: Long-lasting epoxy or silver-infused coatings (reapplied weekly)

-

In shared kitchens or rentals: Easy-to-remove antibacterial mats

-

For elderly spaces: Slip-safe antimicrobial finishes with low odor

Benefits:

-

Cleaner feel underfoot

-

Fewer smells

-

Safe if food is dropped and picked up

-

Better grip when floors get wet

2. Countertops & Food Prep Areas

Where the real action happens—chopping, washing, slicing, stirring. These surfaces need fast, food-safe disinfection.

What to Use:

-

Everyday spray with safe ingredients (like silver, citric acid, or vinegar)

-

Fast-drying disinfectants for busy kitchens

-

Natural sprays for homes with pets or kids

Best spots to treat:

-

Cutting boards

-

Stone or wood countertops

-

Sink edges

-

Fridge and oven handles

How often: After every meal or prep session

3. Dining Tables

Before anyone picks up a fork, make sure the table is clean and safe. Wiping isn’t enough—disinfection matters.

Two options:

-

Quick antibacterial spray before and after meals

-

Invisible protective coating that lasts a few days at a time

Great for:

-

Families (especially with toddlers)

-

Restaurant tabletops (between each guest)

-

School lunchrooms or elderly dining rooms

-

Outdoor tables (with UV-stable spray)

🧴 What Makes a Good Antibacterial Product?

Look for products that say:

-

✅ “Food-safe” or “no rinse required”

-

✅ Kills 99.9% of bacteria

-

✅ Safe for skin contact

-

✅ Low-VOC or fragrance-free

-

✅ Certified under EU or FDA food safety standards

🌱 Better for the Planet, Too

You don’t have to choose between hygiene and sustainability.

Choose products that are:

-

🌿 Biodegradable

-

🔄 Refillable or in recycled packaging

-

🚫 Free from chlorine or harsh solvents

🧼 Final Word: Every Clean Surface Is an Act of Care

Your kitchen is more than just a workspace. Your table is more than just furniture. They’re where you nourish, protect, and share.

With just a few smart products and habits, your food spaces become safer—for family, guests, or the people you serve. Clean doesn’t need to be complicated. It just needs to be intentional.

Comments

Post a Comment