The Underwater Vase: A Bold New Frontier in Ocean Defense and Research

The Underwater Vase: A Bold New Frontier in Ocean Defense and Research

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

As threats and opportunities continue to emerge from beneath the waves, the concept of ocean-based infrastructure has entered a transformative era. The Vase-Class Underwater Defense Structure, inspired by the timeless geometry of an amphora, is a next-generation deep-sea installation that merges defense, research, surveillance, and emergency response into a single, modular, and scalable system. Designed to rest on the seafloor or operate as a mobile platform, the Vase-Class represents a bold reimagining of underwater presence — stable, stealthy, and smart.

Why a Vase?

The amphora-inspired form is not aesthetic coincidence — it is functionally and structurally optimal for high-pressure marine environments:

-

Wide Base: Offers anchoring stability and houses power systems, ballast tanks, and seafloor sensors.

-

Bulbous Midsection: Provides pressurized space for crew, AI command nodes, laboratories, weapon systems, and life support.

-

Narrow Neck: Minimizes hydrodynamic drag and serves as a vertical transition shaft.

-

Flared Top: Hosts antennas, drones, communication arrays, and defensive turrets — often with partial elevation toward the surface.

Recent designs include glass domes made from borosilicate-alumina composite, allowing 360° underwater observation for research, mental resilience, and visual command.

Internal Architecture and Functional Zones

1. Foundation (Base Zone)

-

Self-drilling anchor struts

-

Ballast tanks and stabilization fins

-

Ocean current turbines and thermal gradient harvesters

-

Seafloor seismic, sonar, and temperature sensors

2. Operations & Control Deck

-

AI-assisted mission control

-

Tactical and scientific monitoring stations

-

3D sonar arrays, radar, and satellite uplinks

-

UAV, UUV, and AUV control interfaces

3. Defense Systems

-

Vertical Launch Systems (VLS) for torpedoes and anti-air missiles

-

360° auto-reloading torpedo bays

-

Laser and railgun interceptors

-

Acoustic mine dispensers and smart net defenses

4. Living Quarters and Life Support

-

Algae-based food bioreactors and oxygen recycling

-

Quarters for 20–80 crew members

-

Training, exercise, and medical compartments

-

Escape capsules, shelters, and decompression pods

5. Power and Communication

-

Modular nuclear micro-reactor (optional)

-

Ocean energy harvesters

-

Redundant graphene-based batteries

-

EMP-shielded data and power grid

-

Satellite, optical fiber, and acoustic communication systems

Entry, Exit, and Connectivity

Airlocks

Double-sealed, pressure-balanced chambers for crew and equipment.

Dry Docks

Vehicle bays that allow UUVs, drones, or submarines to dock and operate internally after water evacuation.

Submarine-Compatible Transfer Tunnel

Pressurized telescopic tunnel for direct submarine-to-base personnel and cargo transfer.

Vertical Access Shafts

Elevator tubes connecting the base to surface platforms or shoreline control hubs.

Emergency Egress

Escape capsules and internal pressure shelters in case of flooding, attack, or system failure.

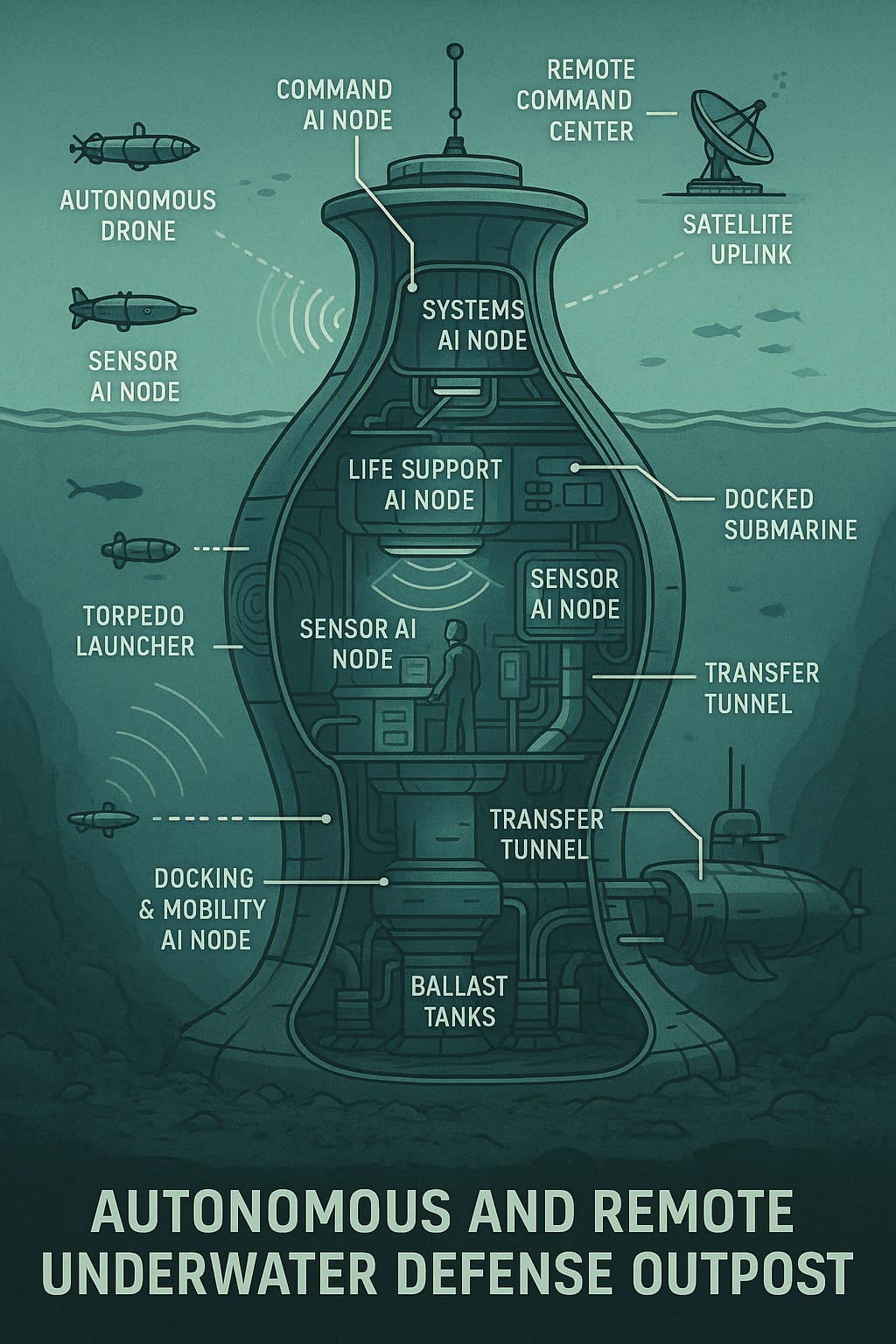

Autonomous and Remote Operations

The Vase-Class supports:

-

Full autonomy via multi-core AI systems

-

Remote control from floating command ships, land-based centers, or tethered submarines

-

Hybrid mode, combining onboard crews with remote AI oversight

Autonomous systems manage power flow, sonar scanning, drone deployment, tactical responses, structural health, and environmental monitoring.

AI Nodes Include:

-

Command AI

-

Systems AI

-

Life Support AI

-

Docking & Mobility AI

-

Sensor AI (acoustic, thermal, chemical, electromagnetic)

Shoreline Integration (Leshe Model)

The structure is factory-built, transported to a shoreline hub (leshe), then:

-

Assembled and tested

-

Floated or lowered into water

-

Towed or self-navigated to its operational site

-

Anchored to seafloor or held in semi-submerged position

Optional connection to land includes:

-

Power and data cables

-

Air and water pipes

-

Submarine shuttle or pressurized elevator tubes

The system is reversible: the unit can be retrieved for maintenance or relocation.

Mobile Variant: Submarine-like Deployment

A deployable version of the Vase-Class base includes:

-

Retractable propulsion pods

-

Foldable anchoring legs

-

Pressure-stable hull for movement

-

Internal ballast control for diving and resurfacing

-

Compatibility with submarine and drone fleets

This variant allows mobile command, stealth patrols, and disaster deployment.

Use Cases Across Domains

| Domain | Application |

|---|---|

| Naval Defense | Monitoring EEZs, launching drones, detecting submarines |

| Submarine Support | Resupply, coordination, intelligence exchange |

| Scientific Research | Coral reef analysis, marine biology, seafloor geology |

| Environmental Monitoring | Ocean temperature, currents, pollution, seismic activity |

| Emergency Response | Rescue base for tsunamis, oil spills, submarine disasters |

| Underwater Tourism | Future glass-domed hotels and deep-sea observation zones |

Strategic Vision: A Global Network

The Vase-Class is designed for scalability and integration:

-

Undersea networks of vases linked by tunnels or sonar grids

-

Regional command chains supported by floating air-sea stations

-

Autonomous drone fleets coordinated from seafloor to surface

-

Permanent ocean infrastructure for defense, science, and diplomacy

Conclusion

The Vase-Class Underwater Defense Structure is more than a base — it is a bold step toward a new era of maritime infrastructure. Designed to endure the deep sea and serve multi-domain operations, it unifies security, sustainability, and science. Its elegant geometry, modular design, AI command, and adaptive deployment make it the foundation for the underwater cities, defense systems, and research missions of the future.

The ocean is no longer the last frontier — it is the next domain of sovereign presence. And the Vase-Class is how we rise to meet it.

The Underwater Vase: A Bold New Frontier in Ocean Defense and Research

In a time when threats come from land, sky, and sea, a new ocean base design is emerging—one that is powerful, multifunctional, and shaped like an ancient amphora. The Vase-Class Underwater Defense Structure is a seafloor-based installation that integrates defense, research, surveillance, and emergency response within a hardened, modular habitat. Its design has now evolved to include glass domes, expanded interior capacity, and enhanced docking for submarines and drones.

Why a Vase?

The amphora-inspired shape is structurally and functionally optimal:

-

Wide base for anchoring, sensors, turbines, and stability

-

Bulbous midsection for crew, control rooms, labs, and operational zones

-

Narrow neck for controlled water flow and internal transit

-

Flared top for communication towers, drone ports, and weapon systems

Glass domes now enhance this structure with 360-degree underwater observation, boosting research and psychological comfort.

Inside the Vase

-

Living Quarters: With full life support, algae-based food systems, and oxygen recycling for 20–80 crew

-

Control Center: Centralized AI-assisted command for sonar, UAVs/UUVs, and satellite uplinks

-

Docking Bays: Dry docks and direct submarine docking for vehicle access and maintenance

-

Observation Domes: Pressure-resistant glass panels for marine study and operator mental wellness

-

Power Systems: Modular reactors, thermal gradient harvesters, and ocean current turbines

Safe Entry and Exit

Multiple entry methods ensure operational flexibility and safety:

-

Airlocks: Double-seal personnel chambers

-

Dry Docks: For submersibles and drone servicing

-

Submarine-Compatible Transfer Tunnel: Telescopic, pressure-equalized corridor enabling door-to-door crew movement

-

Vertical Access Tubes: Linking base to floating or land hubs

-

Emergency Capsules: Eject upward in case of critical breach

Defense and Monitoring Systems

-

VLS tubes, torpedo launchers, laser/railgun turrets

-

AI-enhanced sonar arrays, passive listening, electromagnetic anomaly sensors

-

Mine dispensers, acoustic net defenses

-

Command-AI redundancy, EMP-shielded grid, blast doors, sealing redundancy

Deployment, Mobility, and Shore Integration

-

Factory-Built: Modular construction and shop assembly

-

Leshe-Linked: Shoreline hubs connect to structure via cables, pipes, and control systems

-

Mobile Variant: Self-submersible, recoverable vessel with propulsion and hover-ballast systems

-

Shore-to-Sea Access: Submarines, vertical shafts, or tethered shuttle docks ensure logistical integration

Civil and Military Use Cases

-

Strategic defense of choke points and exclusive economic zones (EEZs)

-

Host for autonomous underwater vehicles (AUVs), unmanned drones, and rescue ops

-

Platform for marine biology, seismic monitoring, and climate research

-

Emergency response node for oil spills, earthquakes, or submarine recovery

-

Visionary use: tourism, glass hotels, and undersea cities

Strategic Future

The Vase-Class structure is a secure, modular, and expandable ocean fortress. Whether protecting borders, exploring marine frontiers, or preparing for disaster response, it symbolizes a new age of strategic underwater infrastructure—where aesthetics, functionality, and resilience converge beneath the waves.

The Underwater Vase: A Bold New Frontier in Ocean Defense and Research

Now with Glass Domes and Expanded Space for Life and Mission Control

In a time when threats come not only from land and sky but also from beneath the waves, a new type of ocean base is emerging — one that is as powerful as it is unusual in shape. Imagine a huge structure on the seafloor that looks like an ancient amphora or vase. But instead of holding water, this one holds crew members, sensors, drones, and advanced defense systems. This is the Vase-Class Underwater Defense Structure — a giant, high-tech base that rests quietly at the bottom of the sea, watching, listening, and protecting.

And now, it's getting bigger, smarter, and more transparent — literally. The newest version includes glass domes, larger interior sections, and new ways for people and machines to enter and exit safely.

Why a Vase?

The idea of shaping an underwater base like a vase may sound strange at first. But the design is based on practical reasons:

-

A wide base keeps the structure stable on the ocean floor and allows for anchors, sensors, and power systems.

-

A curved middle section gives room for people to live and work inside — including control rooms, labs, and sleeping quarters.

-

A narrow neck improves water flow and creates a protected shaft for moving between levels.

-

A flared top allows antennas, drone ports, and defense systems to be placed above the main body of the vase — where they’re less likely to be damaged or seen.

Now, with added glass panels and domes, the structure also includes observation decks where crew members can see outside, study marine life, or monitor nearby activity — all from behind thick, pressure-resistant glass.

What Happens Inside?

Inside the vase are different zones for different purposes:

-

Living Quarters: Crew members can live inside for weeks or months. There are kitchens, sleeping areas, exercise rooms, and even algae gardens for food and oxygen recycling.

-

Control Center: The heart of the vase — where operators monitor sonar, communicate with the surface, and control underwater drones or defense systems.

-

Drone & Submarine Garage: Underwater vehicles can enter the vase through a dry dock. Once inside, water is drained out, and the vehicles can be refueled or repaired.

-

Observation Domes: The new glass areas provide 360-degree views of the ocean, useful for both research and mental health.

-

Power Room: The vase can use nuclear micro-reactors, ocean currents, or even underwater temperature differences to generate electricity.

Safe Entry and Exit

One of the most important parts of any underwater structure is making sure people and machines can get in and out without letting water flood the base.

The vase solves this with:

-

Airlocks: Double-door chambers that drain water and balance pressure before anyone enters the main base.

-

Dry Dock Bays: Large docking rooms that allow drones or small submarines to enter, be sealed off, and then worked on in dry conditions.

-

Vertical Shafts: A long tunnel can connect the vase to a floating platform or a land base. This can be used for crew transfer, cargo, or emergency evacuation.

Why Build It?

The vase isn’t just a cool idea — it’s a real solution for real needs. Here are a few examples of what it can do:

-

Defense: It can detect submarines, launch torpedoes, or monitor borders silently from underwater.

-

Surveillance: With sonar and satellite links, it can track movement across oceans, support nearby ships, and collect intelligence.

-

Research: It can host scientists studying coral reefs, marine animals, or underwater volcanoes.

-

Disaster Response: In case of oil spills, earthquakes, or missing submarines, it can act as a base for rescue drones and communication.

Land-to-Sea Connection

The vase is not built at sea. It’s made in large parts in a factory — then transported to a shoreline hub (called a leshe), where it’s launched into the water like a ship. From there, it can be:

-

Towed or self-driven to its final location

-

Anchored to the seafloor using retractable legs

-

Connected to land by cables, pipes, or shuttle submarines

-

Returned to shore for repairs or upgrades if needed

This makes the vase modular and reusable — like a giant plug-and-play ocean station.

A Look into the Future

The Vase-Class structure represents a big step forward in how we use the ocean — not just for war or defense, but for science, sustainability, and safety. Its glass domes let us see the sea like never before. Its technology allows for full-time deep-sea missions. And its shape — both ancient and futuristic — reminds us that design can be both beautiful and practical.

In the future, underwater vases may line strategic straits, protect islands, monitor sea traffic, and even welcome tourists in glass-walled hotels under the waves. Whether for defense, discovery, or diplomacy — the underwater vase is ready.

The Underwater Vase-Class Structure: Autonomous and Remote-Controlled Deep-Sea Infrastructure

By Ronen Kolton Yehuda (Messiah King RKY)

Introduction

The Vase-Class Underwater Defense Structure is more than a physical installation on the seafloor — it is an intelligent, networked, and optionally autonomous system capable of operating with or without onboard personnel. As threats evolve and oceans become contested arenas for defense, research, and environmental surveillance, the ability to remotely operate and automate deep-sea bases becomes a critical advantage. This article explores how the Vase-Class system integrates remote control, full AI autonomy, semi-autonomous mission profiles, and fail-safe manual override systems.

1. Remote and Autonomous Operation: Overview

The Vase-Class structure can be operated in three modes:

-

Fully Autonomous Mode

All mission protocols are handled by onboard AI systems, including surveillance, threat response, environmental monitoring, and energy management. -

Remote-Controlled Mode

The base is operated in real-time from a command center on land, aboard ships, or from satellite-linked control hubs. Human operators guide strategic decisions while the system handles routine tasks. -

Hybrid Mode

The base runs autonomously with remote human oversight and the option for manual intervention in complex or critical scenarios.

2. Central AI System ("Vase-AI")

Features:

-

Mission Management: Monitors and prioritizes objectives across defense, surveillance, and research domains

-

Threat Assessment Engine: Uses pattern recognition and anomaly detection to assess sonar, electromagnetic, and visual data

-

Behavioral Logic: Can simulate crew decision trees to manage emergencies, scientific protocols, or defense escalation

-

Machine Learning Module: Continuously adapts to terrain, ocean conditions, and adversary tactics

Security:

-

Encrypted communication channels

-

EMP-hardened core processors

-

Redundant backup nodes with air-gapped integrity

-

Ethical override based on preset international maritime protocols

3. Remote Command and Monitoring

Command Interfaces:

-

Shore-based command facilities (military or research)

-

Satellite-linked mobile command stations (airborne or naval)

-

UAV relay systems for ocean-based temporary uplinks

Functions Available Remotely:

-

Activate/deactivate sensors, weapons, or drones

-

Control power systems and life support

-

Launch or recall autonomous underwater vehicles (AUVs)

-

Override base AI in emergencies

-

Initiate seal-off protocols or remote evacuation

4. Communication and Data Exchange

Systems:

-

Satellite Uplink Towers: Extendable masts or buoy-linked dishes

-

Undersea Fiber Optics: For fixed regional networks or tethered installations

-

UAV Relay Drones: Mobile aerial links launched from the canopy

-

Quantum-Encrypted Channels: For top-level military use

-

Low-Frequency Acoustic Modems: For deep-sea, long-range backup signals

Redundancy and Resilience:

-

Every system has a duplicate channel

-

Autonomy continues even if disconnected

-

Data is stored in tamper-proof black-box systems

5. Autonomous Mission Scenarios

| Scenario | Autonomous Tasks |

|---|---|

| Military Surveillance | Continuous sonar sweep, enemy detection, alert protocols |

| Environmental Research | Sample collection via ROVs, data logging, climate tracking |

| Disaster Response | Tsunami/seismic event detection, auto-deploy drones |

| Hostile Encounter | Auto-lock on targets, warn or engage based on ROE |

| Resupply Coordination | Receive supply submarines, auto-dock, transfer payloads |

6. Redundancy and Safety Systems

-

Triple-Failover Command Logic: Ensures base never enters rogue state

-

Biometric Lockouts: Remote override requires multilayered authentication

-

Auto-Isolation: In case of cyber intrusion or sabotage, segments shut off independently

-

Manual Override Ports: Accessible only from reinforced interior control rooms or by authorized submarine docking

7. Scaled Network Operations

Multiple Vase-Class units can be deployed as an interlinked Undersea Grid, managed by a central AI or coordinated human-AI command:

-

Shared sonar and monitoring fields

-

Autonomous handoff of drones or surveillance responsibilities

-

Adaptive swarm behavior (e.g., shifting energy load or sharing sensor inputs)

-

Support for "Underwater Highway Nodes" in deep-sea traffic and logistics

8. Future Prospects

-

Integration with Naval Combat Clouds: Bases will join a real-time, distributed maritime defense network

-

Fleet Coordination: Manage swarms of AUVs, UUVs, and smart mines

-

Smart Habitats: Act as hubs for underwater cities or hotels — monitored and serviced entirely by AI

-

Civilian Applications: Autonomous environmental monitoring for governments, NGOs, or universities

Conclusion

The Vase-Class Underwater Structure is more than a defense base — it is a living, thinking infrastructure node. With full autonomous capabilities, advanced remote control, and secure AI mission management, it can function independently in the ocean’s most hostile environments. In the age of underwater competition, disaster response, and planetary monitoring, autonomous and remotely managed ocean architecture is not just an advantage — it’s essential.

Author:

Ronen Kolton Yehuda (Messiah King RKY)

Visionary Strategist | Defense Technologist | Creator of the Vase-Class System

Autonomous and Remote Operation Framework for the Vase-Class Underwater Defense Structure

Technical Systems Architecture and AI-Controlled Mission Profiles

Abstract

The Vase-Class Underwater Defense Structure, designed for seafloor deployment, is equipped with full-spectrum autonomous capabilities and remote-control interfaces for military, scientific, and emergency operations. This paper details the embedded control architecture, operational AI layers, telemetry infrastructure, mission adaptability, and security protocols that enable remote and unmanned operation in high-risk oceanic environments.

1. Introduction

Underwater bases face a unique triad of challenges: environmental isolation, communication latency, and risk of manned exposure. The Vase-Class architecture addresses these through integrated autonomous systems, allowing for fully unmanned operation, semi-supervised remote control, and hybrid deployment strategies.

This capability is essential for strategic defense zones, high-pressure research environments, and deep-sea disaster response, where human presence is constrained or unnecessary.

2. Command Modalities

| Mode | Description | Use Case |

|---|---|---|

| Manual-Crewed | Onboard crew controls all systems; AI assists | Long-term research, full tactical command presence |

| Semi-Autonomous | AI controls subsystems; remote command center oversees high-level decisions | Low-risk zones, standard surveillance |

| Fully Autonomous | Entire base runs via embedded AI with autonomous mission execution | High-risk zones, stealth surveillance, deep-sea deployments |

3. AI Control Architecture

3.1 Core AI Nodes

The Vase-Class is powered by a distributed AI cluster, with fault-tolerant nodes assigned per operational domain:

-

Command AI Node: Strategic decision-making, threat response, drone deployment

-

Systems AI Node: Power regulation, structural integrity, ballast management

-

Life Support AI Node: Oxygen cycling, thermal regulation, bioreactor control

-

Sensor AI Node: Acoustic, thermal, chemical, and electromagnetic data analysis

-

Docking & Mobility AI Node: Submarine docking, drone bay operations, self-submersion

All AI modules operate under a central mission kernel, protected by quantum-encrypted firmware and an EMP-shielded operating grid.

3.2 Autonomy Features

-

Predictive failure detection using machine-learning telemetry analysis

-

Dynamic energy reallocation (e.g., diverting power during stealth or combat)

-

Adaptive mission switching: defense → rescue → observation

-

Autonomous drone swarm coordination for external monitoring

4. Remote Operation Infrastructure

4.1 Communication Protocols

-

Primary: Encrypted satellite uplink (optical/microwave hybrid)

-

Secondary: Fiber-optic tether to floating or coastal control stations

-

Tertiary: Acoustic modulation (low-bandwidth fallback for long-range)

4.2 Remote Interface Capabilities

-

Full control of sensors, drones, weapons, and AI mission states

-

Real-time diagnostics and failure alerts

-

3D virtual twin interface for off-site inspection and simulation

-

Emergency command override with dead-man switch functionality

4.3 Control Center Integration

-

Land-based command hubs (leshe)

-

Naval fleet interface terminals

-

Submarine-linked command bridges with tunnel or wireless access

5. Redundancy and Cybersecurity

5.1 System Redundancy

-

Triple-redundant power buses

-

Isolated fallback AI nodes in hardened core

-

Blast-sealed server vault with automatic locking on breach

5.2 Security Measures

-

Quantum-key encryption on all control channels

-

Intrusion detection algorithms in firmware and uplink nodes

-

Physical kill-switch for remote deactivation (AI-locked unless authorized)

6. Operational Scenarios

| Scenario | Autonomous Action | Remote Role |

|---|---|---|

| Torpedo Threat Detected | AI activates sonar jamming, deploys countermeasures | Remote HQ notified, override possible |

| Submarine Docking Request | AI verifies ID, extends transfer tunnel | Remote confirms authentication logs |

| Deep-Sea Survey | AI dispatches drones, collects samples | Remote receives and analyzes real-time data |

| System Breach / Flooding | AI isolates compartments, auto-seals blast doors | Remote monitors interior cam feeds |

7. Integration with Mobile Units and Networks

The Vase-Class structure can network with:

-

Mobile submarine fleets: direct docking and data exchange

-

Underwater drone swarms: remote coordination for mapping and defense

-

Other vase units: interlinked via sonar mesh or fiber cables for regional command

-

Floating air-sea command bases: full uplink via vertical access tubes or relay buoys

8. Maintenance and Diagnostics

-

Continuous AI-driven system integrity checks

-

Remote firmware updates and subsystem patching

-

Predictive diagnostics for propulsion units, seals, and reactors

-

Robotic arm maintenance available in mobile variants

9. Conclusion

The autonomous and remotely operated design of the Vase-Class Underwater Defense Structure enables it to function as a next-generation seafloor outpost — capable of strategic autonomy, real-time remote control, and resilient mission execution without surface dependency. As underwater operations grow in complexity, these intelligent architectures will become the standard for both defense and scientific infrastructure on the ocean floor.

Author:

Ronen Kolton Yehuda (Messiah King RKY)

Defense Technologist | Strategic Systems Architect | Founder of the Vase-Class Concept

Vase-Class Underwater Defense Structure

Overview

The Vase-Class structure is a multi-functional, vertically integrated underwater base shaped like a vase. Designed to be anchored on the seafloor, it serves as a:

- Naval defense outpost

- Surveillance and monitoring station

- Docking hub for submersibles and drones

- Launch platform for unmanned vehicles and torpedoes

- Communication and data relay node

- Research and disaster response base

Structural Design

Shape:

- Wide base: For anchoring and stability

- Narrow neck: For pressure and flow control

- Bulbous midsection: For primary operations and living quarters

- Flared top: For communication antennas and drone ports

Materials:

- Reinforced submarine-grade titanium alloy and composite ceramics

- Internal pressure-compensated chambers

- Algae-repellent and stealth coating

Core Functional Zones

1. Foundation (Base)

- Deep-sea anchor system with self-drilling piles

- Anti-mining defense grid

- Power storage, ballast tanks, and emergency buoyancy system

- Seafloor sensor arrays (seismic, sonar, thermal)

2. Operations & Control Deck (Midsection)

- Command center with tactical interface

- Real-time 3D sonar and radar mapping

- Satellite uplink and encrypted naval communications

- Autonomous vehicle bay (UUV, AUV, ROV)

3. Defense Systems

- Torpedo launcher bays (360° azimuth)

- Vertical launch system (VLS) tubes for anti-ship and air-defense missiles

- Laser/interception turrets for incoming threats

- Mine deployment and net defense

4. Monitoring and Surveillance Suite

- Long-range sonar arrays

- Acoustic signature detection systems

- AI-enhanced threat detection

- Marine traffic analysis systems

- Satellite and surface relay towers

5. Human Occupancy & Logistics

- Crew quarters for 20–60 personnel

- Emergency evacuation pods and escape hatch system

- Oxygen recycling, freshwater generation

- Food, energy, and waste recycling system

- Labs for biology, defense R&D, and marine science

Power System

- Hybrid energy:

- Nuclear mini-reactor (optional)

- Ocean current turbines

- Tidal & thermal gradient harvesters

- Backup battery arrays

- Redundant power network with EMP shielding

Optional Modules

- Drone Swarm Launch Dome

- Floating surface platform with vertical elevator tube

- Mini-submarine docking garage

- Underwater tunnel connectors to nearby vases

- Decoy & camouflage cloak systems

Use Cases

- Naval choke point defense

- Strategic deterrent in EEZ waters

- Undersea intelligence gathering

- Anti-submarine warfare (ASW) base

- Marine environment monitoring station

- Disaster response hub for oil spills, tsunamis

Vase-Class Underwater Defense Structure: A Technical Overview

Abstract

The Vase-Class Underwater Defense Structure is a modular, seafloor-anchored installation designed for multi-domain maritime operations. Drawing from hydrodynamic and structural principles inspired by amphora-shaped geometry, it integrates surveillance, combat readiness, autonomous systems, and scientific capability within a hardened subaqueous vessel. This paper outlines its architectural design, operational components, and use cases in modern naval strategy.

1. Introduction

As naval threats evolve to include submarines, unmanned vehicles, and stealth incursions, coastal and strategic underwater infrastructure becomes a critical asset. The Vase-Class structure offers a compact, camouflaged, and resilient solution deployable in territorial waters, strategic choke points, or undersea economic zones. Its amphora-inspired shape enables optimal stability, hydrodynamics, and compartmentalization.

2. Structural Design

2.1 Geometric Configuration

- Base: Wide-bottom, embedded in seabed via self-anchoring drill piles and weighted ballast rings.

- Midsection: Pressurized cylindrical habitat ring with integrated control and life-support systems.

- Neck: Vertical shaft for access tunnels, communications towers, and airlock systems.

- Top Dome: Antenna arrays, drone hatches, and laser/sonar ports.

This configuration ensures both minimal drag and maximal volumetric use within a pressure-resistant form factor.

2.2 Materials

- Titanium-alloy exostructure (Grade 5 or 23)

- Carbon composite pressure hulls (with ceramic-reinforced armor plating)

- Internal anti-vibration mounting for electronics and life support

- Acoustic-dampening outer layer for stealth

3. Systems and Subsystems

3.1 Power Supply

- Hybrid propulsion and energy system:

- Ocean current turbines integrated into anchor struts

- Thermal gradient generators

- Nuclear micro-reactor (optional for permanent installations)

- Solar buoys (surface-linked backup)

3.2 Life Support and Habitability

- Pressurized crew quarters (supporting 10–60 personnel)

- Modular life support with oxygen generation, CO₂ scrubbing, and freshwater distillation

- Food storage and algae-based nutritional recycling unit

- Emergency evacuation pods and upward-launch escape capsules

3.3 Surveillance and Monitoring

- Passive and active sonar arrays with 360° coverage

- AI-enhanced acoustic signature analysis

- Thermal and chemical sensors for enemy detection and environment tracking

- Satellite uplink and encrypted communication relay towers (via periscope or buoy)

3.4 Defense Systems

- Vertical Launch System (VLS) for underwater and anti-air missiles

- Torpedo bay with smart reload system

- Laser and railgun mounts (surface or semi-surface dome)

- Underwater mine deployment and acoustic net defenses

3.5 Docking and Deployment

- 2–6 vehicle docking bays (UUVs, AUVs, crewed minisubs)

- External robotic arms for hull maintenance, cable deployment, or salvage

- Upper hatch platform for UAV or USV operations

4. Use Scenarios

| Scenario Type | Function |

|---|---|

| Military Surveillance | Long-term monitoring of hostile or contested maritime zones |

| Territorial Defense | Enforcing maritime sovereignty with real-time tracking and deterrence |

| Choke Point Control | Securing straits and canals from underwater incursions or smuggling |

| Submarine Support Station | Providing recharging, rearming, or coordination for submarine fleets |

| Disaster Recovery Node | Hosting rescue drones, seismic sensors, or emergency payload delivery |

| Environmental Monitoring | Observing coral reefs, currents, and climate metrics in real-time |

| Dual-Use Scientific Module | Conducting deep-sea biology, AI hydrography, or strategic mineral studies |

5. Deployment & Scalability

The Vase-Class unit is modular and may be:

- Standalone

- Networked via underwater tunnels or wireless relays

- Integrated into larger underwater cities or defense networks

Deployment requires a pre-surveyed anchor zone, transported via heavy-lift submersible or semi-submerged platform, followed by autonomous or crewed positioning, drilling, and activation.

6. Conclusion

The Vase-Class Underwater Defense Structure represents a transformative paradigm in underwater military infrastructure — merging stealth, survivability, autonomous systems, and multi-role capacity. In future conflicts and maritime stability operations, such deep-sea assets will serve not only as defense posts but as strategic command, research, and sustainability nodes across the ocean floor.

Entering the Underwater Vase: How Crews Access and Stay Dry in a Deep-Sea Defense Structure

Underwater defense bases like the “vase-class” structure operate under extreme pressure, surrounded by water at all times. One of the biggest engineering challenges is how to enter or exit the base without letting water in, and how to move personnel, drones, or submarines in and out safely.

This article explains the solutions and technologies that allow safe access to the underwater structure.

1. The Challenge: Pressure and Sealing

At depths of 100 to 300 meters (or more), the surrounding water pressure is immense — and any breach or opening would cause flooding, danger, or complete system failure. Therefore, all entry points must be:

- Completely sealed when not in use

- Pressure-balanced when in operation

- Able to handle emergency exits or rescue missions

2. Main Entry Systems

🔸 Airlock Chambers (Personnel Entry)

- Located at the top or lower neck of the vase

- Includes a double-door system:

- Outer door opens to the water

- Inner door opens to the dry base

- When a person or drone enters, the chamber is sealed, and water is drained using powerful pumps.

- After pressure equalization, the inner door opens safely into the main structure.

🔸 Dry Dock Bay (For Vehicles or Drones)

- A large interior submersible garage where underwater vehicles (UUVs, minisubs) can dock

- Entry via a retractable pressure door

- Once a drone enters, the area is sealed, water is pumped out, and maintenance can begin

Common Systems:

- Hydraulically sealed docking gate

- AI-assisted docking guidance system

- Pressure equalization before opening internal doors

3. Top Entry – Vertical Access Tube

- Some vase structures are connected by a vertical tube to a floating platform or sea buoy

- A pressurized elevator or tunnel connects surface personnel or cargo directly to the base

- This tube has multiple seal points, allowing it to isolate and handle pressure at different levels

4. Waterproofing and Sealing Technologies

- Electromagnetic sealing rings: React instantly to pressure changes and auto-lock

- Self-healing polymer gaskets: Expand and seal micro-cracks when exposed to water

- Redundant bulkheads: Multiple doors or plates to prevent total failure if one seal is compromised

5. Emergency Systems

In case of a critical breach:

- Auto-closing blast doors segment the structure

- Emergency ballast systems allow quick surfacing of top modules

- Personal escape pods eject through upward hatches and rise to the surface automatically

- Pressure shelters are built into lower levels for safe waiting

6. Surface or Tethered Entry (Optional for Shallow Zones)

For structures in shallow waters (20–50 meters):

- Divers or submarines can enter through a wet deck hatch

- These hatches are mechanically or magnetically sealed

- Designed for frequent personnel movement in calm zones

7. Redundancy and AI Control

All access systems are controlled by a central AI that:

- Monitors pressure, water intrusion, and door status

- Prevents human error by locking incompatible doors

- Responds instantly to breaches or unauthorized access

Conclusion

Accessing a deep underwater base may sound like science fiction, but it’s very real — using airlocks, dry docks, vertical shafts, and advanced sealing systems, modern engineering can make it as safe as any spacecraft or submarine. The “vase-class” underwater defense station combines traditional submarine logic with permanent, stable architecture, providing secure and dry entry points in the most hostile environment on Earth: the deep sea.

Submarine-Compatible Entry System for Vase-Class Underwater Structures

Direct Docking Architecture for Secure Undersea Personnel and Cargo Transfer

Abstract

This paper presents an advanced entry system integrated into the Vase-Class Underwater Defense Structure, enabling direct docking of submarines or submersible vehicles through a sealed, modular hatch interface. This architecture allows door-to-door movement without exposure to water or pressure differentials—facilitating high-speed, stealthy, and secure operations. The system supports rapid deployment, resupply, and personnel transfer under deep-sea conditions and extends the functionality of the underwater base for defense, intelligence, and logistics.

1. Introduction

As underwater infrastructure expands, secure and efficient transfer of personnel, equipment, and data between mobile and static underwater assets becomes critical. Traditional airlocks and dry docks are effective but time-consuming and limited in emergency responsiveness. This new interface allows submarines or minisubs to dock and connect directly to the vase’s hull through a unified docking collar, achieving a pressurized corridor link, akin to jet-bridge boarding in aerospace contexts.

2. Docking Interface Architecture

2.1 External Submarine Docking Collar

-

Location: Midsection or lower side of the vase structure

-

Design:

-

Universal mating ring (UMR) compatible with NATO-standard submarine docking ports

-

Hydraulic locking clamps for rigid connection under variable current

-

Sensor-guided alignment system with AI-assisted docking (visual + acoustic beacons)

-

2.2 Sealed Transfer Tunnel

-

Expandable transfer tunnel (telescopic or accordion-style)

-

Built from reinforced pressure-rated composite with magnetic ring seals

-

Pressurization-controlled tunnel equalizes vessel and base atmosphere

-

Fully walkable width (~1.2–1.6 m internal diameter) with handrails and lighting

3. Internal Access Module

3.1 Submarine Entry Door

-

Airlock-integrated submarine side hatch remains sealed until docking is complete

-

High-strength bi-directional locking system allows initiation from either side

-

Interior equipped with biometric ID system, decontamination mist, and emergency shut-off valves

3.2 Base Entry Port

-

Located at the crew logistics zone of the vase

-

Triple-seal magnetically latched inner hatch

-

Auto-sealing bulkheads in case of breach or disconnect failure

4. Safety Systems and Redundancy

| System | Function |

|---|---|

| Redundant Magnetic Seals | Ensure airtight integrity even under minor pressure shifts |

| Pressure Monitoring Chambers | Constant differential sensors with automated valve control |

| Emergency Cut-off Gates | Blast-resistant sliding plates that can isolate the corridor in under 1.2 seconds |

| Buoyant Detachment Protocol | If the submarine loses power, the interface detaches safely and reseals both ends |

| Manual Override | Mechanical release and manual lockout valves in case of AI or power failure |

5. Use Scenarios and Benefits

| Use Case | Description |

|---|---|

| Stealth Personnel Deployment | Deliver special forces directly into the vase base via submarine |

| Medical Evacuation | Transfer injured crew to a recovery submarine without exposing them to pressure changes |

| Resupply | Send vital equipment and rations using dedicated supply minisubs |

| Rapid Redeployment | Evacuate personnel from the vase in the event of imminent threat |

| Data & Intel Transfer | Use encrypted physical data relays via submarine (no surface link required) |

6. Integration with Mobile Vase-Class Units

Mobile versions of the vase structure (with propulsion) can rendezvous with a submarine mid-mission. The hydrodynamic profile of the vase allows semi-drift alignment while dynamic positioning thrusters assist with stable side-by-side locking.

In these versions:

-

The transfer collar is retractable

-

It can switch between submarine docking and dry dock entry

-

It includes a magnetic alignment rail system to pull the vessels together for final locking

7. Materials and Engineering

-

Docking Collar: Titanium Grade 5 with smart-alloy impact dampening

-

Tunnel Housing: Carbon-borosilicate composite with high tensile resilience

-

Seals: Multi-layered polymer-metallic magnetic gasket rings

-

Interior Tunnel Shell: Anti-fog, anti-bacterial laminate with integrated LED lighting

-

Power & Data Transfer Ports: Optical and conductive ports for shared systems (e.g. refueling or file upload)

8. Deployment and Maintenance

-

The submarine docking system is built modularly and can be upgraded in port

-

Routine maintenance includes seal integrity testing, sensor recalibration, and pressure test simulations

-

Docking logs are automatically recorded for both the vase AI and the submarine’s control systems

9. Conclusion

The submarine-compatible docking module for the Vase-Class Underwater Structure introduces a new standard for undersea logistics, defense mobility, and mission efficiency. By enabling direct, sealed, and fast door-to-door connectivity, it minimizes vulnerability, maximizes operational flexibility, and supports diverse scenarios ranging from covert military ops to humanitarian rescue missions. As underwater infrastructure becomes increasingly critical, such modular and mobile interfacing will shape the next frontier of subsea architecture.

Mobile Vase-Class Structure: A Submarine-Like, Deployable Underwater Base

In the future of maritime defense and exploration, mobility is as important as stability. Enter the mobile vase-class underwater structure — a hybrid design that combines the portability of a submarine, the functionality of a seafloor base, and the modular architecture of a land-to-sea platform.

This structure is built to launch from land or port, carry personnel and equipment, travel across the sea, and deploy underwater — either temporarily or permanently.

1. Design Concept: Submersible, Deployable, and Reversible

The mobile vase-class structure is:

- Shaped like a vase or amphora for optimal stability and internal volume

- Capable of being transported over land or by ship

- Self-submersible — it can dive, anchor to the seafloor, and stabilize

- Capable of resurfacing and returning to port for repair, resupply, or reassignment

This makes it ideal for:

- Rapid deployment in a conflict or disaster

- Temporary underwater operations

- Mobile surveillance or research missions

2. Transportation and Deployment

🔸 On Land

- Transported on heavy wheeled trailers or rail platforms

- Loaded with crew, supplies, and autonomous systems

- Maintains internal pressure during transit

🔸 At Sea

- Floats like a heavy, self-balanced barge or semi-submersible vessel

- Moves using low-speed propulsion pods or can be towed

- Equipped with stabilization fins and GPS guidance

🔸 Submersion Process

- Anchors at selected site

- Ballast tanks fill to submerge the structure

- Propulsion modules guide descent

- Anchoring struts deploy into seafloor

- Stabilization systems activate

Result: The structure becomes a secure, unmoving seafloor base.

3. Features and Systems

🧷 Dual-Mode Pressure Hull

- Handles both travel and deep-sea conditions

- Self-sealing, anti-corrosion titanium composite

⚙️ Retractable Propulsion and Landing Gear

- Marine jet thrusters or ducted propellers for underwater positioning

- Foldable anchor legs that extend like a lunar lander

- Optional hover ballast mode for shallow hover ops

🛰 Communication and Navigation

- Satellite-guided surface mode

- Sonar and seabed mapping for positioning

- Autonomous navigation for long-range relocations

🧭 Living and Operations Module

- Crew quarters, command center, AI control, and laboratories

- Power from modular nuclear micro-reactor or hybrid batteries

- Drone garage and airlock systems still included

4. Waterproof Mobility and Re-Entry

To ensure safe movement between surface and depth, the mobile vase uses:

- Multi-chamber ballast system for slow, safe descent and surfacing

- External and internal pressure compensation

- Magnetic seals and reinforced hatches

- Crew enters via surface hatch or airlock module

- Entire structure remains pressurized during the full transition

5. Recovery and Relocation

After mission completion:

- Water is expelled from ballast tanks

- Propulsion is activated

- Anchor legs retract

- Structure ascends, stabilizes at the surface

- Towed or self-propelled back to port or towed to new destination

6. Use Cases

| Use Case | Description |

|---|---|

| Rapid Undersea Deployment | Bring base to location, deploy it temporarily or semi-permanently |

| Submerged Military Command Post | Mobile underwater HQ for regional operations |

| Scientific Ocean Missions | Moveable research base for deep sea, coral, volcanoes, or wrecks |

| Disaster Response Base | Deployable underwater hub near crisis zones |

| Covert Surveillance Node | Move in stealth, submerge, monitor, and move again |

Conclusion

The mobile vase-class underwater structure represents the next step in ocean-based infrastructure — a unit that acts like a movable fortress, submarine, and habitat, all in one. It offers the flexibility of relocation with the strength of permanent underwater architecture. As nations expand maritime operations into deeper and more complex territories, this hybrid solution could become a standard for mobile ocean defense, exploration, and emergency response.

Here is a concept proposal for connecting the underwater vase-class structure to land or a shoreline facility (leshe), and designing it to be delivered and deployed from a dockyard or shop facility like modular industrial equipment.

Connecting the Underwater Vase Structure to Land: Shoreline Deployment and Access Concept

Objective

Design a modular, vase-shaped underwater base that can:

- Be manufactured and pre-assembled on land (in a shop/factory)

- Be transported to the shoreline (leshe or port)

- Be launched, towed, or self-navigated to sea

- Be connected to land through cables, pipes, or vertical access shafts

- Support reversible deployment: able to return to port for upgrades

1. Shop-Based Manufacturing and Delivery

The structure is built as a modular system:

- Main vase body (pre-wired and pressure-ready)

- Detachable propulsion pod ring

- Detachable anchor legs or base ring

- Interior subsystems pre-installed (life support, control, power)

Delivery from shop:

- Transported on flatbed truck or rail platform

- Shipped to leshe (shoreline support dock)

- Crane-lowered or rolled into water using a submersible transport cradle

2. Shoreline (Leshe) Connection Hub

At the shoreline, the vase structure connects to land-based systems via:

🔌 Power and Data Cable

- Buried undersea cable connects from land to the vase

- Supplies electricity (if needed) and high-bandwidth fiber optics

- Protected with armor tubing and sensor-triggered defenses

🌬 Air and Water Supply Pipes (optional)

- Connects to surface desalination or air filtration systems

- Ensures backup oxygen, fresh water, and waste management if needed

🧭 Control Room / Command Uplink

- Land-based operations room can monitor or remotely control the base

- Emergency override and shutdown protocols included

3. Deployment at Sea from Leshe

If detached for sea deployment:

- Floated off loading ramp or platform into shallow bay

- Self-propelled or towed by vessel to target coordinates

- Submerges using built-in ballast tanks

- Anchor legs lock to seabed

- Final systems activate automatically or via remote trigger

4. Access From Land or Shoreline

Option 1: Vertical Access Tube

- A sealed elevator tube extends from structure to floating surface hub

- Surface hub connects to shoreline by floating dock, pontoon bridge, or long gangway

Option 2: Submarine Shuttle or Tethered Dock

- Small submersible travels between base and shoreline port

- Automatically docks with vase airlock

- Tethered line or underwater rail supports movement and safety

5. Reversibility and Maintenance

- Ballast tanks can expel water to refloat the base

- Detach from anchor platform

- Return to surface

- Towed or navigated back to shoreline dock for upgrades

6. Applications

| Use Case | Description |

|---|---|

| Military Coastal Outpost | Seamlessly integrates defense systems into a nation's shoreline |

| Research Base Extension | Enables deep-sea research while still connected to university facilities |

| Tourism or Underwater Hotel | Allows safe public access via shoreline pier or access tube |

| Emergency Response Node | Can be launched from shop, floated from leshe, and deployed quickly |

Conclusion

By designing the vase-class underwater structure as a pre-assembled, mobile module that connects directly to land and can be delivered like industrial cargo, the system becomes flexible, fast to deploy, and cost-efficient. Whether for national defense, marine research, or sustainable infrastructure, this shore-connected architecture unlocks a new era in underwater living and operations.

Abstract

The Vase-Class Underwater Defense Structure is an advanced, multi-functional, deep-sea base optimized for long-term maritime defense, surveillance, and scientific operations. Evolving from original amphora-based geometries, this enlarged model incorporates reinforced observation glass domes, expanded crew capacity, and enhanced modular subsystems. This article outlines its updated structural configuration, defensive systems, access architecture, and strategic deployment potential.

1. Introduction

As global naval strategies expand into undersea theaters, nations seek permanent, intelligent infrastructure for maritime dominance, environmental control, and disaster mitigation. The enhanced Vase-Class structure represents a synthesis of advanced hydrodynamics, materials engineering, and modular living-space design — capable of operating in hostile deep-sea conditions with strategic deterrent value.

2. Structural Enhancements

2.1 Shape and Scale

-

Overall Height: 60–120 meters

-

Base Diameter: 35–60 meters

-

Volume Increase: +150% compared to standard variant

-

Key Zones:

-

Foundation Ring with reinforced ballast and anchor struts

-

Midsection Dome with panoramic glass observation zones

-

Neck Shaft for vertical transit and access

-

Top Canopy for antennae, drones, and emergency hatches

-

2.2 Glass Integration

-

Material: Pressure-rated borosilicate-alumina composite glass (tested to 400 m depth)

-

Use Cases:

-

Research observatories

-

Tactical operations visibility

-

Psychological support (natural light imitation)

-

-

Features:

-

Anti-reflective coating

-

Electrically tintable

-

Integrated with internal HUD systems

-

3. Life Support and Human Systems

3.1 Expanded Crew Operations

-

Capacity: Up to 80 full-time personnel

-

Functions: Defense, research, AI monitoring, engineering, logistics

-

Living Modules:

-

Pressurized living quarters

-

Nutrition systems (algae bioreactors, vertical gardens)

-

Entertainment, training, and briefing rooms

-

Emergency pressure pods and surface-bound escape systems

-

3.2 Health and Psychological Resilience

-

Full-spectrum lighting mimicking circadian rhythm

-

Real-time communication with surface command

-

Transparent viewports for psychological relief

-

Seismic isolation and acoustic dampening

4. Defense and Operational Systems

4.1 Defense Systems

-

Integrated Combat Ring in midsection and canopy:

-

Vertical Launch Systems (VLS) for underwater and aerial threats

-

Torpedo tubes (auto-loading, 360° rotation)

-

Railguns, laser interceptors, and kinetic projectile launchers

-

Underwater mine dispensers and AI-controlled net systems

-

4.2 Surveillance & Monitoring

-

Panoramic sonar array mesh

-

Electromagnetic anomaly detectors

-

AI-based acoustic fingerprinting

-

Long-range passive listening devices

-

Live-feed from underwater drones and UAVs

4.3 Command and AI Integration

-

Central AI for situational control

-

Human-AI cooperative defense coordination

-

Redundant offline operation mode

-

Encrypted relay uplink and backup satellite dishes

5. Access, Sealing & Safety

5.1 Entry Points

-

Airlocks: Triple-seal magnetic hatches (upper, lower, side)

-

Dry Dock: Expands for submarine and drone vehicle access

-

Vertical Elevator Shaft: Sealed pressurized lift to floating platform

5.2 Safety Systems

-

Electromagnetic seal redundancy

-

Auto-sealing blast doors

-

Integrated emergency shelters (3 levels)

-

Independent oxygen generators & thermal shelters

6. Power System

-

Primary:

-

Modular nuclear micro-reactor (EM-shielded)

-

Ocean current turbines

-

-

Secondary:

-

Thermal and pressure gradient energy harvesters

-

Surface solar buoy backup

-

-

Battery: Solid-state, layered graphene-capacitor storage

-

Network: Fully redundant, EMP-resistant smart grid

7. Modular Expansions and Network

-

Inter-vase tunnel connectors for regional grid

-

Floating platforms for aircraft and satellite link

-

Expandable science pods and drone hangars

-

Detachable modules for future upgrades

-

Mobile versions retain docking compatibility

8. Strategic Use Cases

| Use Case | Description |

|---|---|

| Submarine Detection Hub | Constant monitoring in contested waters |

| Marine Surveillance Anchor | Border zone protection and mapping |

| Mobile Defense Launchpad | Hosting, refueling, and coordinating UUVs and autonomous torpedoes |

| Scientific Base | Seafloor geology, biology, and climate tracking |

| Emergency Operations Node | Tsunami and spill response with onboard disaster tech |

9. Manufacturing and Deployment

-

Manufacture: In high-security defense yards, segmentally built

-

Transport: By barge, floating cradle, or specialized submersible trailer

-

Deployment:

-

Anchored via robotic legs or magnetic seabed claws

-

Remotely activated or crew-deployed

-

Can be retrieved and returned to port

-

10. Conclusion

The updated Vase-Class structure offers a new paradigm in underwater infrastructure — combining military utility, research capabilities, and psychological resilience within a modular, glass-integrated, pressure-stable habitat. Scalable, reversible, and multi-use, it prepares navies and scientists alike for a future of secure deep-sea presence.

The Underwater Vase: A New Type of Defense and Monitoring Base Beneath the Sea

In a world where threats can come from land, air, and now increasingly from below the surface, the concept of underwater defense infrastructure is gaining global attention. One of the most promising ideas is a deep-sea base shaped like a vase — a design that’s both functional and symbolic.

A Strategic Underwater Base

This “underwater vase” is not a decorative object — it is a military and surveillance station, placed on the seafloor, designed to carry out multiple roles:

- Monitoring ocean activity and undersea traffic

- Launching unmanned underwater vehicles (UUVs)

- Detecting submarines and sea mines

- Serving as a protected command center

- Hosting sensors, torpedoes, and defense systems

- Supporting marine research or environmental observation

Such a base would be installed in key locations such as chokepoints, territorial waters, or offshore defense zones.

Why a Vase?

The vase shape is chosen for both engineering and operational reasons:

1. Stability on the Seafloor

- A wide bottom ensures the structure can anchor securely into the seabed, even under strong currents or seismic activity.

- This wide base allows for installation of power systems, including turbines that harness ocean currents.

2. Efficient Volume Use

- The midsection — which bulges outward — provides room for equipment, crew quarters, and operations. This area contains most of the functional systems.

- The shape allows different internal pressure zones and sections for defense, life support, and control.

3. Controlled Access and Protection

- A narrow “neck” section minimizes water flow turbulence and serves as a vertical passageway, connecting the top to the lower structure.

- This limits the number of access points and improves security.

4. Strategic Top Section

- The top of the vase is flared and often extends upward with a semi-dome. It can house:

- Communication antennas

- Sonar and radar arrays

- Drone launch ports

- Laser or missile launchers

- Emergency buoyant systems

Inside the Underwater Vase

The interior is divided into sections:

- Lower Base: Anchoring system, power generation (tidal, thermal, or mini-reactor), storage units.

- Main Core: Operations room, AI surveillance control, torpedo/missile bays, crew quarters, emergency chambers.

- Upper Zone: Launch systems, satellite uplink, radar/sonar masts, escape pod hatches.

Each structure can be fully autonomous or manned, depending on mission needs. Most designs include airlocks, robotic arms, and docking stations for underwater drones and submarines.

Multi-Use Functionality

Beyond military use, the structure can support:

- Disaster monitoring (like early warnings for tsunamis or earthquakes)

- Environmental studies (tracking ocean temperatures, pollution, or marine life)

- Search-and-rescue missions (providing base support for deep-sea emergencies)

- Scientific missions (such as seabed mineral exploration or biology)

Conclusion

The underwater vase is not just a creative design — it is a powerful new type of infrastructure that merges defense, monitoring, sustainability, and research. Its shape is based on principles of pressure resistance, efficient space usage, and deep-sea stability. As countries continue to expand their maritime capabilities, structures like these could become common in international waters, protecting coastlines from beneath the waves.

The Underwater Vase: A New Generation of Deep-Sea Defense and Discovery Bases

As the world’s oceans become increasingly strategic zones for defense, research, and environmental monitoring, a bold new solution has emerged from the depths: the Vase-Class Underwater Structure. This seafloor installation, shaped like an ancient amphora, is a multifunctional underwater base — blending military strength, scientific utility, and futuristic design.

The Purpose of the Vase-Class Base

The underwater vase isn’t just a structure — it’s a secure command hub, an observation post, and a technological stronghold all in one. Installed in coastal or deep-sea regions, these bases are built to:

-

Monitor ocean traffic using sonar and surveillance systems

-

Host torpedoes, anti-submarine weapons, and drones

-

Launch and receive unmanned underwater vehicles (UUVs)

-

Support deep-sea scientific research and climate monitoring

-

Act as forward bases for disaster response missions

-

Provide long-term crew operations under high pressure conditions

A Shape Made for the Sea

The structure’s signature vase shape isn’t just for looks — it’s designed to handle the immense pressure of deep-sea environments while maximizing functionality.

-

Wide Base: Anchors the structure to the seabed and houses heavy systems like power generation, stabilizers, and emergency buoyancy controls.

-

Bulbous Midsection: Contains the majority of interior space for crew quarters, control rooms, laboratories, drone garages, and storage systems.

-

Narrow Neck: Serves as the primary access channel and houses vertical transit systems such as elevators and escape pods.

-

Flared Top: Equipped with communication towers, sonar arrays, and drone launch ports. The structure’s top may even reach toward the surface through a tether or vertical shaft.

Living and Working Below the Sea

Inside the vase, up to 60–80 crew members can live and work for extended missions. Life support systems are fully integrated, including:

-

Oxygen generation and recycling

-

Freshwater distillation

-

Nutritional algae-based food production

-

Waste-to-energy processing systems

-

Pressurized escape capsules for emergency evacuation

Observation domes made from ultra-strong, pressure-rated glass provide a view of the surrounding marine world — useful for both scientific work and psychological well-being.

Access Systems and Safety Features

Getting in and out of an underwater base — and keeping the ocean out — is a major challenge. The vase uses:

-

Airlocks: Pressurized double-door systems for personnel and drones

-

Dry Dock Bays: Large sealed garages where underwater vehicles can enter, be drained, and serviced

-

Vertical Access Tubes: Connecting the vase to floating platforms or land stations

-

AI-Controlled Sealing Systems: For flood prevention, breach detection, and auto-shutdown

-

Emergency Shelters: Reinforced interior pods in case of structural damage

Powered by the Ocean

The vase base runs on hybrid energy, including:

-

Miniature nuclear reactor (for extended missions)

-

Tidal and thermal gradient generators

-

Ocean current turbines

-

Backup graphene-based batteries

-

Solar buoys, if connected to the surface

All power systems are EMP-shielded and fully redundant for continuous operation during conflict or natural disasters.

Applications Across Civil and Military Domains

| Use Case | Description |

|---|---|

| Naval Defense Post | Detects submarines, monitors enemy activity, and deploys drones or torpedoes. |

| Environmental Monitoring | Gathers real-time data on ocean currents, temperature, and pollution. |

| Scientific Research Station | Hosts marine biologists and climate scientists. |

| Emergency Operations Node | Can deploy rescue drones during tsunamis or search for wreckage. |

| Underwater Tourism or Hospitality | With upgrades, it could serve as a future underwater hotel with glass observatories. |

From Land to Seafloor: Deployment Process

The structure is pre-built in sections and shipped to a shoreline launch facility (also called a leshe). From there:

-

It is floated into shallow waters or lowered from a cradle.

-

It is towed or self-navigated to its target location.

-

Ballast tanks fill, slowly sinking the base into position.

-

Anchor legs or drills lock into the seabed.

-

All systems activate remotely or by onboard crew.

The base can also detach and return to port if needed for upgrades or relocation.

Looking Ahead: A Global Undersea Network

The Vase-Class base represents more than a single structure. In the future, these installations could:

-

Link together via underwater tunnels or sonar relays

-

Form seafloor networks across oceans

-

Support autonomous fleets of underwater drones

-

Protect international maritime infrastructure

-

Create permanent undersea research cities

Conclusion

The underwater vase is not a fantasy — it’s a next-generation infrastructure for a future where nations need to see, respond, and operate below the ocean’s surface. With its strong frame, modular design, and clear glass domes, the vase is poised to redefine how we live, defend, and explore under the sea.

The Underwater Vase

A Bold New Frontier in Ocean Defense and Research

Introduction

In a world where threats and opportunities emerge from land, air, and increasingly from beneath the ocean, a revolutionary concept is redefining maritime infrastructure: the Vase-Class Underwater Defense Structure. Shaped like an ancient amphora, this next-generation underwater base fuses military strength, scientific functionality, and architectural elegance. Designed to rest on the seafloor, it serves as a multifunctional fortress for surveillance, defense, exploration, and emergency response.

This article presents the full architecture, systems, deployment methods, and strategic vision of the Vase-Class structure, integrating technical, operational, and futuristic perspectives.

Why a Vase?

The amphora-like shape is not only symbolic—it is structurally and functionally optimal for deep-sea stability, modularity, and internal space efficiency.

-

Wide Base: Anchors securely to the seafloor, houses power turbines, ballast tanks, sensors, and stabilization systems.

-

Bulbous Midsection: Offers expansive internal volume for crew quarters, command centers, laboratories, and vehicle bays.

-

Narrow Neck: Supports controlled vertical access, communications towers, and minimizes drag.

-

Flared Top: Hosts sonar, antennas, drone launch bays, laser and missile defense systems.

The newest generation includes glass observation domes crafted from pressure-rated composites, enhancing visibility, psychological comfort, and research capacity.

Internal Structure and Zones

1. Foundation (Base)

-

Self-drilling anchor struts

-

Ballast tanks and emergency buoyancy systems

-

Seafloor sensor arrays (seismic, thermal, sonar)

-

Power generation: tidal turbines, thermal gradients, or modular nuclear units

2. Operations & Control Deck

-

AI-assisted mission control

-

Real-time sonar and radar tracking

-

Satellite uplink and encrypted naval communications

-

Docking and control bays for AUVs, UUVs, ROVs, and drones

3. Defense & Weapon Systems

-

Vertical Launch Systems (VLS) for underwater/airborne threats

-

Torpedo launchers with smart reloading

-

Laser and railgun interceptors

-

Mine dispersers and acoustic defense nets

4. Monitoring & Surveillance

-

360° AI-enhanced sonar arrays

-

Electromagnetic anomaly sensors

-

Long-range acoustic signature detection

-

Real-time drone feed and thermal imaging

5. Human Habitation and Logistics

-

Life support for 20–80 crew

-

Oxygen recycling and freshwater generation

-

Algae-based food bioreactors and vertical farming

-

Quarters, command rooms, exercise, and research labs

-

Escape pods and emergency shelters with pressure support

Power and Communication

-

Primary Power: Ocean current turbines, thermal gradient systems, optional nuclear micro-reactor

-

Backup Systems: Solid-state batteries, graphene-capacitor storage, solar surface buoys

-

Communication: Satellite, encrypted optical links, surface relay drones

-

EMP Shielding: Redundant and hardened against electronic warfare

Entry, Exit, and Safety Systems

Airlocks

-

Titanium and carbon fiber double-door systems

-

Full pressure equalization and biometric security

Dry Docks

-

Large docking bays for drones, mini-submarines, and vehicles

-

AI-guided docking and hydraulic pressure seal

Submarine Transfer Tunnel

-

Telescopic, pressurized tunnel with magnetic ring seals

-

Direct door-to-door crew and cargo movement from submarine to base

Vertical Access Tubes

-

Connect to surface platforms or leshe shore facilities

-

Include pressurized elevator lifts and escape ladders

Emergency Features

-

Escape capsules that eject and ascend automatically

-

Self-sealing blast doors and internal isolation systems

-

AI-monitored environmental and breach control

Mobile Vase-Class Variant

A deployable version of the vase structure allows:

-

Land-to-sea transport via trailer or ship

-

Self-submersion with ballast tanks and propulsion pods

-

Retrieval and relocation, functioning like a submarine habitat

-

Use in mobile command missions, surveillance patrols, or disaster deployments

It includes foldable landing legs, propulsion fins, and onboard AI navigation.

Shoreline Integration (Leshe)

Each Vase-Class structure can be built in a factory and delivered to a shoreline hub (leshe), where it is:

-

Assembled and pre-wired

-

Transported into shallow waters

-

Towed or self-propelled to final underwater site

-

Connected to land via:

-

Power and data cables

-

Freshwater and air pipes (optional)

-

Submarine shuttle or access shaft

-

The design allows reversible deployment—bases can be detached and returned to port.

Modular Network Potential

Vase-Class structures can form a networked grid connected by:

-

Undersea tunnels

-

Relay buoys

-

AI-linked command nodes

They can scale to support:

-

Underwater cities

-

Interconnected defense zones

-

Autonomous drone fleets

-

Environmental and seismic monitoring grids

Strategic Use Cases

| Domain | Function |

|---|---|

| Naval Defense Post | Monitor EEZs, detect submarines, deploy countermeasures |

| Submarine Support Station | Refueling, repairs, and coordination for fleets |

| Marine Research Base | Host climate scientists, marine biologists, and seabed geologists |

| Environmental Monitoring | Observe coral reefs, ocean currents, pollution, and thermal changes |

| Emergency Response Node | Base for drone rescue operations, tsunami early warnings, oil spill action |

| Mobile Military Command | Deployable HQ for regional conflict or natural disaster |

| Underwater Tourism / Hotel | Glass dome observation decks for future tourism |

Materials and Engineering

-

Structure: Grade-5 titanium, ceramic-reinforced composites

-

Glass Domes: Borosilicate-alumina composite, 400m+ depth resistance

-

Seals: Electromagnetic rings, self-healing gaskets

-

Internal Coating: Acoustic dampening, antibacterial, anti-fog surfaces

Deployment and Maintenance

-

Built in modular sections (hull, propulsion, anchor base)

-

Deployed using floating platforms or heavy-lift vessels

-

Autonomous positioning with GPS and sonar

-

Maintenance includes robotic inspections, seal testing, and module upgrades

Looking Ahead: A Global Undersea Future

Vase-Class structures represent a leap forward in maritime infrastructure — combining stealth, intelligence, resilience, and livability. As geopolitical tensions rise and oceans become a theater for both collaboration and conflict, these bases could be the cornerstones of national security, scientific discovery, and international coordination beneath the sea.

Whether lining strategic straits, supporting drone networks, hosting undersea labs, or welcoming the first glass-dome hotels — the underwater vase is not just ready for the future. It is the future.

Author:

Ronen Kolton Yehuda (Messiah King RKY)

Visionary Strategist | Defense Technologist | Founder of the Vase-Class Concept

The Underwater Vase

A Bold New Frontier in Subsea Defense, Intelligence, and Research

By Ronen Kolton Yehuda (Messiah King RKY)

I. Introduction: From Surface to Seafloor

As naval warfare, environmental monitoring, and strategic communications extend beneath the surface, traditional maritime infrastructure faces limitations. A new paradigm is rising from the ocean floor: the Vase-Class Underwater Defense Structure.

Shaped like an amphora — wide at the base, narrow at the neck, and flared at the top — this seafloor-anchored base combines deep-sea resilience, AI-powered autonomy, and multi-role versatility. Designed for deployment in high-value zones such as chokepoints, EEZ boundaries, and offshore research corridors, the Vase-Class structure is not only a defense node but also a permanent subsea intelligence, operations, and scientific outpost.

II. Structural Design: Form Follows Function

1. Geometry and Stability

The signature vase shape is structurally and hydrodynamically optimized:

-

Base: Anchored deep into the seabed with self-drilling struts; houses ballast tanks, current turbines, and sensor arrays.

-

Midsection: Largest interior volume — includes AI command decks, defense systems, living quarters, and labs.

-

Neck: Vertical shaft with reduced water resistance, suitable for access tunnels and internal elevators.

-

Flared Top: Integrated with communication towers, drone ports, launch systems, and external turrets.

2. Materials and Armor

-

Exostructure: Submarine-grade titanium alloy with ceramic composite plating

-

Domes: Pressure-rated borosilicate-alumina glass for 360° external visibility

-

Coatings: Acoustic-dampening, algae-resistant, radar-absorbing polymer layers

III. Operational Capabilities

A. Command and Control Zones

-

Multi-core AI system with nodes dedicated to:

-

Mission command

-